- 1-866-294-3191

- Open Monday to Friday 8am to 5pm

- Emergency Callout Available

Blocks

Block Video

Care and Maintenance

VGD SNATCH BLOCK BRONZE BUSHING

-Intermittent usage-

VGD Snatch Blocks – Maintenance

Snatch blocks are a pulley block with a side plate that can be opened so that you don’t have to thread the rope through the pulley. Generally, Snatch blocks are used in applications to move loads intermittently over short distances, as opposed to continuous service with long lifts. They are often used in conjunction with a winch in a recovery application were secure points may be offset from pulling direction. These snatch blocks are furnished with a bronze bushing which is a friction bearing needing lubrication to provide best service life.

VGD Snatch Blocks – Maintenance

Forged alloy hooks – heat treated – with latch

• Shackle/Hook forged steel – heat treated

• Forged steel swivel tees, yokes and shafts

• Bronze bush with grease nipple

• Fittings are painted yellow for quick recognition

• Designed for intermittent use with low line speed

• Ultimate load 4 x Working Load Limit (WLL)

MAINTENANCE:

To ensure peak efficiency and see an extended service life, it is necessary that blocks be inspected and maintained at frequent intervals:

Inspection procedures for any sign of wear or damage, such as:

Worn or damaged shafts, bushings, slide plates and pins hooks or shackles: replace any part showing signs of wear or damage!

Hook latch for proper fit and operation. Replace deformed latches!

These particular blocks feature bronze bushings, which are not self-lubricating.

They are designed for infrequent or intermediate use with low line speed.

Observe the following lubrication schedule.

Assuming normal usage conditions moderate – Lubricate every 6 – 8 hours of continuous use.

Assuming normal usage conditions Intermittent – Lubricate once weekly

MAINTENANCE:

To ensure peak efficiency and sea and extended service life, it is necessary that blocks be

inspected and maintained at frequent intervals:

Inspection procedures for any sign of wear or damage, such as:

Worn or damaged shifts bushings slide plates and pins hooks or shackles: replace any

part showing signs of wear or damage!

Hook latch for proper fit and operation. Replace deformed latches!

These particular blocks feature bronze bushings, which are not self-lubricating.

They are designed for infrequent or intermediate use with low line speed.

Observe the following lubrication schedule.

• Moderate use: Every 6-8 hours

• Intermittent operation: Once weekly

LOADS:

Throughout this catalogue, the term working load limit (abbreviated: WLL) is being used.

It refers to the maximum load or force which a product is designed to support under normal

operating and environmental conditions and the product being in and as new condition.

IMPORTANT:

The total load on a snatch block, and therefore also on any fittings which are attached

to the block, is usually considerably greater than the actual load lifted or pulled.

The deciding factor in determining the total load on a single line block is the angle

between the lead line and the load line:

FAILURE TO OBSERVE THESE WARNINGS MAY RESULT IN SERIOUS INJURY OR DEATH!

All inspections, maintenance, block lifting design and rigging of blocks should be performed by a qualified/competent person (as defined by ANSI/ASME B.30)

• ALWAYS inspect snatch blocks before use (see maintenance section below). If during the inspection the unit is found to be damaged, cracked or deformed it must be removed from service immediately for repair.

• ALWAYS design and rig snatch block systems so that the load will not slip or fall.

• ALWAYS design lifting systems with the appropriate number of sheave assemblies to prevent premature sheave, bearing or wire rope wear and failure.

• ALWAYS make sure that all workers keep their hands, bodies and clothing away from the block sheaves, and pinch points where the wire rope makes contact with any part of the block or load.

• ALWAYS make sure that the hook NOT that latch supports the load.

• ALWAYS make sure that snatch blocks are regularly inspected, lubricated and maintained (see lubrication section).

• NEVER exceed the working load limit (WLL).

• NEVER sideload a snatch block.

• NEVER weld snatch blocks or load supporting parts.

• NEVER lift or transport loads over or near people.

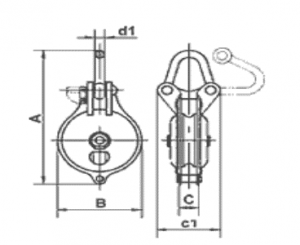

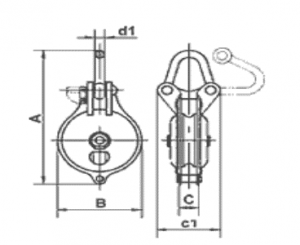

VQ Double Sheave Yarding Block

6202-2RS BALL BEARING

Fast and strong for light-duty and high-speed applications Smooth sealed roller bearing action. Pull pin to use as snatch block. Painted. No more lubing the bearings! These yarding blocks come complete with sealed ball bearings. 6202-2RS. Rubber contact seal bearings. Easy to replace should you need to.

| Measurements in inches | Weight | WARNING: Do not exceed the listed load limits | ||||||

|---|---|---|---|---|---|---|---|---|

| Yarding Block WLL Ton | Sheave Dia. | A | B | C | C-1 | D-1 | Lbs/Pc | Product Code |

| .50 | 3" | 7.01 | 3.35 | 1.97 | 4.09 | .47 | 3.97 | 29362300 |

| 1.00 | 4" | 9.25 | 4.76 | 2.40 | 4.45 | .63 | 6.18 | 29362400 |

| 1.50 | 5" | 12.04 | 5.71 | 2.87 | 5.00 | .71 | 12.12 | 29362500 |

| 2.00 | 6" | 13.78 | 7.09 | 3.27 | 5.63 | .87 | 18.74 | 29362600 |

| 4.00 | 8" | 16.73 | 8.86 | 3.66 | 8.43 | 1.10 | 36.37 | 29362800 |

| Ultimate Load: 3x the working Load Limit (WLL) |   |

pages

- Marking GP Shackles

- ANTOX

- Cable & Wire Rope

- Firefighting Promo Page 2024

- What is VGD?

- What is VQ

- Paperless

- University of Vanguard

- Abrasives/Brushes

- Firefighting Promotion Thank you

- Firefighting Promotion Order Form

- Calculators

- Resources and Useful Links

- STEEL WEIGHT CALCULATOR

- Specialty Steel

- Hardware

- Contact

- Industrial Knives

- Welding

- Home

© 2024 Vanguard Steel Ltd. All Right Reserved