- 1-866-294-3191

- Open Monday to Friday 8am to 5pm

- Emergency Callout Available

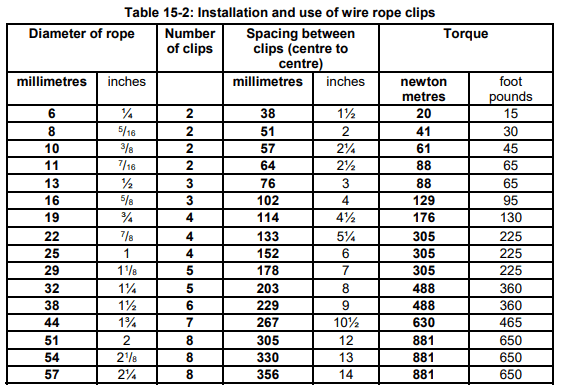

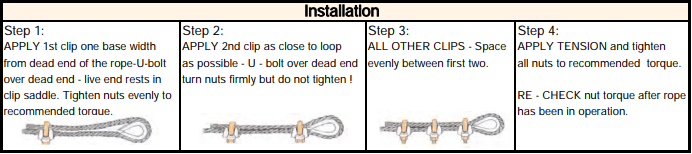

- 7/16″ and smaller require a minimum 2 clips.

- Also, the strength is reduced by min 15%. Check your rigging charge for details.

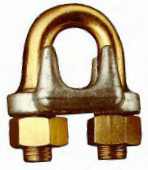

Secure Excellence: Choose the Authenticity of Golden Pin Drop Forged

– Look for the Distinctive Color -

The Drop Forged Golden Pin isn’t just a component; it’s the epitome of excellence and reliability. Amidst a sea of imitations and alternatives, the distinction lies not just in the name but in the unparalleled quality embedded within each pin. It’s not merely about possessing a pin; it’s about securing a vital element that guarantees steadfast performance and durability, standing as a testament to uncompromised craftsmanship and precision engineering.

In a market cluttered with replicas, ensuring authenticity becomes paramount. The golden hue isn’t just a color; it’s a symbol of legitimacy and quality assurance. When acquiring the Drop Forged Golden Pin, it’s crucial to seek out this distinct hue, as it’s the hallmark that sets it apart from imitators. This color isn’t just a cosmetic choice; it’s a deliberate selection, reflecting the meticulously designed coating that fortifies the pin against corrosion and wear, ensuring longevity and reliability in the most demanding environments.

Amidst the competitive landscape where replicas attempt to mimic the unparalleled quality of the Drop Forged Golden Pin, the assurance lies in the color. Insisting on and verifying the presence of this golden hue is akin to safeguarding against subpar substitutes. It’s not just about acquiring a pin; it’s about investing in assurance, reliability, and unwavering quality. The unmistakable golden color isn’t just a recommendation; it’s a beacon guiding you toward the pinnacle of durability and performance amidst a crowd of imitators.

Wire Rope Clips

Occupational Health and Safety Regulation

GENERAL REQUIREMENTS

Wire rope

splices

15.23 Wire rope splices made using wire rope clips must(a) use double the number of clips specified by the manufacturer or Table 15-2 for a single loop termination, when forming a lap splice, or(b) use the number of clips specified by the manufacturer or Table 15-2 foreach loop termination, when forming a double loop splice.

(1) A turnback eye splice made using wire rope clips must use the

number of clips

(a) specified by the manufacturer for each turnback eye termination,

or

(b) if not specified by the manufacturer, specified in Table 15-2.

(2) A lap splice made using wire rope clips must use double the number

of clips

(a) specified by the manufacturer for a turnback eye termination, or

(b) if not specified by the manufacturer, specified in Table 15-2.

Explanatory Notes:

The intent of current section 15.23(a) is that twice the number of wire rope clips required to form a

turnback eye termination must be used to form a lap splice in wire rope. However, there has been some

misinterpretation of this requirement by stakeholders.

The purpose of the amendments is to clarify that twice the number of wire rope clips specified by the wire

rope clip manufacturer for a turnback eye termination must be used for making lap splices or, in the

absence of the wire rope clip manufacturer’s instructions, twice the number of wire rope clips specified in

Table 15-2 must be used.

The term “loop termination”, which is currently used in section 15.23, will be replaced by the term

“turnback eye termination” in order to achieve consistency with terminology used by wire rope clip

manufacturers.

The amendments are for clarification purposes only; there will be no change in the intent of the regulation.

Video

pages

- Marking GP Shackles

- ANTOX

- Cable & Wire Rope

- Firefighting Promo Page 2024

- What is VGD?

- What is VQ

- Paperless

- University of Vanguard

- Abrasives/Brushes

- Firefighting Promotion Thank you

- Firefighting Promotion Order Form

- Calculators

- Resources and Useful Links

- STEEL WEIGHT CALCULATOR

- Specialty Steel

- Hardware

- Contact

- Industrial Knives

- Welding

- Home

© 2024 Vanguard Steel Ltd. All Right Reserved