- 1-866-294-3191

- Open Monday to Friday 8am to 5pm

- Emergency Callout Available

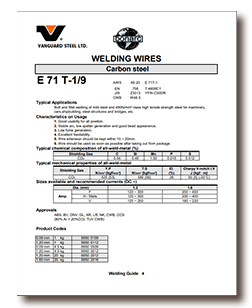

E71T-1/9M

Suitable welding positions

AWS A5.20 E 71T-1

EN 758 T 460RC1

JIS Z3313 YFW-C50DR

CWB W48.5

CWB to CSA W48-14

Classification: E491 T1-C1 A3-CS1-H8 (E491 T-9-H8)

E491 T1-M20A3-CS1-H8 (E491 T-9M-H8)

AWS/ASME A5.36/A5.36M:2016

Typical applications

Gas shielded flux cored welding wire that can be used for all-position welding. It is intended for semi-automatic and automatic single and multiple pass welding of 490 MPa high tensile steel. Engineered to yield weld-metal mechanical properties down to temperature of -30 ° C (-20° F), with gas mixtures of Argon + 20% CO2 to 100% CO2•

Commonly used when welding of structural steels, bridge building, construction equipment, ship building, farm machinery, and general carbon steel fabrications.

Characteristics on usage

- Titania type flux cored wire for all-position welding

- Excellent mechanical properties

- X-Ray quality welds

- Good impact at low temperatures

- Excellent usability, very stable arc

- Easy slag removal, very little spatter generated and smooth bead shape

Typical chemical composition of all-weld-metal (%)

| Shielding Gas | C | Si | Mn | P | S | ||||||||||||||||||||||||||||||||||

| CO2 | 0.04 | 0.45 | 1.30 | 0.015 | 0.012 | ||||||||||||||||||||||||||||||||||

Sizes available and recommended currents (DC +)

| Dia. (mm) | 1.2 1.6 | |||||||||||||||||||||||||||||||||||||||||||

| Amp. | F | 120 ~ 300 | 200 ~ 450 | |||||||||||||||||||||||||||||||||||||||||

| H – fillets | 120 ~ 300 | 200 ~ 400 | ||||||||||||||||||||||||||||||||||||||||||

| V | 120 ~ 250 | 180 ~ 220 | ||||||||||||||||||||||||||||||||||||||||||

Approvals

ABS, BV, DNV, GL, KR, LR, NK, CWB, CCS (80% Ar + 20%CO2 ·TUV CWB)

Typical mechanical properties of all-weld-metal | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| Shielding Gas | Y.P N/mm² {kgf/mm²} | T.S N/mm² {kgf/mm²} | EI. (%) | Charpy V-notch I.V J {kgf · m} | |||||||||||||||||||||||||||||||||||||||||||||||||

| CO2 | 520 {53} | 580 {59} | 29 | 50 {5} (-20°C) | |||||||||||||||||||||||||||||||||||||||||||||||||

Product Codes

| 0.9 mm .035 | 1 kg | 6950 0109 | ||||||||||||||||||

| 1.20 mm .045 | 1 kg | 6950 0112 | ||||||||||||||||||

| 0.9 mm .035 | 4.5 kg | 6950 0509 | ||||||||||||||||||

| 1.20 mm .045 | 4.5 kg | 6950 0512 | ||||||||||||||||||

| 1.20 mm .045 | 20 kg | 6950 2012 | ||||||||||||||||||

| 1.60 mm .062 | 20 kg | 6950 2016 | ||||||||||||||||||

pages

- Marking GP Shackles

- ANTOX

- Cable & Wire Rope

- Firefighting Promo Page 2024

- What is VGD?

- What is VQ

- Paperless

- University of Vanguard

- Abrasives/Brushes

- Firefighting Promotion Thank you

- Firefighting Promotion Order Form

- Calculators

- Resources and Useful Links

- STEEL WEIGHT CALCULATOR

- Specialty Steel

- Hardware

- Contact

- Industrial Knives

- Welding

- Home

© 2024 Vanguard Steel Ltd. All Right Reserved