- 1-866-294-3191

- Open Monday to Friday 8am to 5pm

- Emergency Callout Available

4340 HTSR

(Red)AISI /SAE 4340 (UNS G 43400)

NICKEL-CHROMIUM-MOLYBDENUM STEEL

Size Range

3/4″ – 30″

TYPICAL APPLICATIONS

COUPLINGS, HEAVY DUTY SHAFTING, GEARS, DIES, HIGH STRENGTH MACHINE PARTS,

CRANKSHAFTS, ARBORS, HIGH TENSILE BOLTS AND STUDS, MINE-DRILLING PARTS,

BORING BARS, DOWN HOLE DRILLING COMPONENTS ETC.

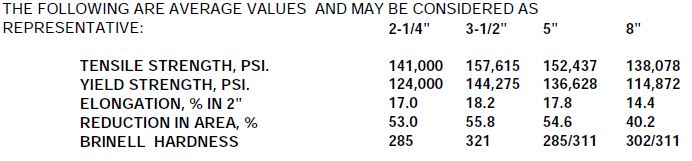

MECHANICAL PROPERTIES – HEAT TREATED AND STRESS-RELIEVED

ASTM A 434 / BD

THE FOLLOWING ARE AVERAGE VALUES AND MAY BE CONSIDERED AS

THE “KING” OF THE HARDENING GRADES OF CONSTRUCTIONAL ALLOY STEELS. A RICH ALLOY CONTENT, THIS NICKEL-CHROMIUM-MOLYBDENUM STEEL, POSSESSES MUCH DEEPER HARDENABILITY THEN THE 4100 SERIES. THIS IS THE MOST EXTENSIVELY USED MACHINERY STEEL WITH AN EXCEPTIONAL RANGE OF STRENGTH, TOUGHNESS AND DUCTILITY. THE ADVANTAGE IS REALIZED PRINCIPALLY WHERE HIGH STRENGTH IS REQUIRED IN HEAVY SECTIONS. THE HIGH FATIGUE-TENSILE RATIO OF 4340 MAKES IT IDEAL FOR HIGHLY STRESSED PARTS OPERATING UNDER THE MOST SEVERE CONDITIONS, AND MAY BE USED IN BOTH ELEVATED AND LOW TEMPERATURE ENVIRONMENT. IT HAS REMARKABLE NON-DISTORTING PROPERTIES FOR AN ALLOY STEEL. IT HAS GOOD WEAR RESISTANCE AND SHOULD BE USED WHERE THE GREATEST MARGIN OF SAFETY IS DESIRED.

© 2025 Vanguard Steel Ltd. All Right Reserved