- 1-866-294-3191

- Open Monday to Friday 8am to 5pm

- Emergency Callout Available

1018

(Silver) AISI/SAE 1018 ASTM A 108 – UNS G 10180

Size Range

1/4″ – 4-1/2″

TYPICAL APPLICATIONS

SUITABLE FOR PARTS REQUIRING COLD FORMING, SUCH AS CRIMPING, BENDING, OR SWAGING. ESPECIALLY SUITABLE FOR CARBURIZED PARTS REQUIRING SOFT CORE AND HIGH SURFACE HARDNESS, SUCH AS GEARS, PINIONS, WORMS, KING PINS, RATCHETS, DOGS, ETC. STRENGTH MACHINE PARTS, CRANKSHAFTS, ARBORS, HIGH TENSILE BOLTS AND STUDS, MINE-DRILLING PARTS, BORING BARS, DOWN HOLE DRILLING COMPONENTS ETC.

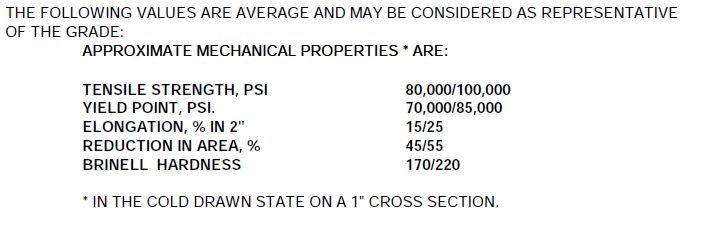

MECHANICAL PROPERTIES

THE FOLLOWING ARE AVERAGE VALUES AND MAY BE CONSIDERED AS

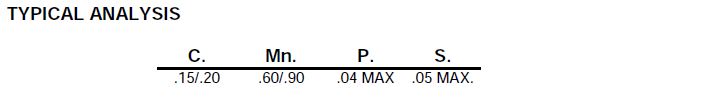

A LOW-CARBON STEEL, HAVING HIGHER MANGANESE CONTENT THAN CERTAIN OTHER LOW CARBON STEELS, SUCH AS 1020. BEING RICHER IN MANGANESE, 1018 IS A BETTER STEEL FOR CARBURIZED PARTS, SINCE IT PRODUCES A HARDER AND MORE UNIFORM CASE. IT ALSO HAS HIGHER MECHANICAL PROPERTIES AND BETTER MACHINING CHARACTERISTICS. THE HOT ROLLED BARS USED IN THE MANUFACTURE OF THIS PRODUCT ARE OF SPECIAL QUALITY.

MOST COLD FINISHED BARS ARE PRODUCED BY COLD DRAWING. IN THIS PROCESS,

OVERSIZE HOT ROLLED BARS, WHICH HAVE BEEN CLEANED TO REMOVE SCALE, ARE DRAWN THROUGH DIES TO THE REQUIRED SIZE. THE LARGER SIZES ARE GENERALLY TURNED AND POLISHED, THE HOT ROLLED BARS HAVING BEEN MACHINE TURNED, RATHER THAN DRAWN, FOLLOWED BY ABRASIVE POLISHING. TURNED AND POLISHED BARS TEND TO HAVE A SOMEWHAT BRIGHTER FINISH THAN COLD DRAWN BARS.

pages

- Marking GP Shackles

- ANTOX

- Cable & Wire Rope

- Firefighting Promo Page 2024

- What is VGD?

- What is VQ

- Paperless

- University of Vanguard

- Abrasives/Brushes

- Firefighting Promotion Thank you

- Firefighting Promotion Order Form

- Calculators

- Resources and Useful Links

- STEEL WEIGHT CALCULATOR

- Specialty Steel

- Hardware

- Contact

- Industrial Knives

- Welding

- Home

© 2024 Vanguard Steel Ltd. All Right Reserved