CHROME PLATE 1045 TG&P

AISI/SAE 1045 CHROME PLATED SHAFTING-SUPPLIED IN FIBRE TUBES

Size Range

1/2″ – 6″

12mm – 160mm

CHROME PLATING

FINISHED THICKNESS OF CHROME .001″ MINIMUM PER SIDE

HARDNESS OF CHROME 69-71 RC

SURFACE FINISH RMS. 16 MAX.

TYPICAL APPLICATIONS

HYDRAULIC SHAFTING, PUMP SHAFTS, PISTON RODS, ETC.

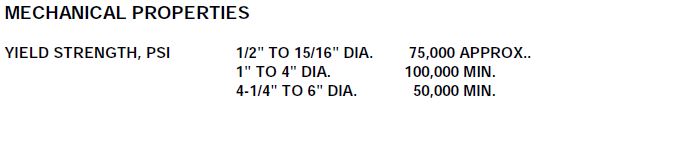

MECHANICAL PROPERTIES

THE FOLLOWING ARE AVERAGE VALUES AND MAY BE CONSIDERED AS

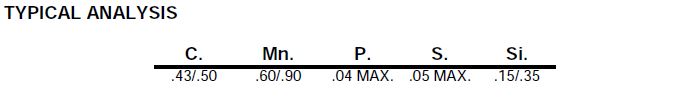

THE STEEL USED IS C1045/1050 COLD FINISHED SHAFTING TO ASTM A-108-90A.

SIZE TOLERANCES ARE TO ASTM STANDARD SPECIFICATIONS A 29/A 29M

PRECISION GROUND SHAFTING REPRESENTS THE HIGHEST DEGREE OF OVER-ALL ACCURACY, CONCENTRICITY, STRAIGHTNESS, AND SURFACE PERFECTION ATTAINABLE IN COMMERCIAL PRACTICE. AFTER BEING GROUND ON A CENTERLESS GRINDER, BARS ARE POLISHED TO A SURFACE FINISH OF RMS. 25 MAX.

THE BARS ARE HARD CHROME PLATED BY ELECTROLYTICALLY DEPOSITED LAYERS OF

CHROMIUM METAL ON THE SURFACE AND CONFERS THE IMPORTANT PROPERTIES

OF CORROSION RESISTANCE AND WEAR RESISTANCE. BEING THAT IT IS VERY SMOOTH IT HAS A LOW COEFFICIENCY TO FRICTION.