Grade 100 VQ Chain

Introducing VGD’s VQ Grade 100 Chain, a premier lifting solution engineered for the most demanding industrial applications.

Our Grade 100 chain, distinguished by its vibrant blue colour, represents the pinnacle of quality and strength. Crafted from heat-treated alloy steel, this chain is meticulously designed and approved for overhead lifting, towing, and binder chain applications. Available in sizes ranging from 1/4″ to 5/8″, it can be purchased by the foot or in bulk drum quantities to suit your specific needs.

Our Grade 100 chain features easily identifiable markings on the links, spaced every 10″ to 16″ or every few links, depending on the grade. These markings, required by NACM specifications, ensure that users can quickly and accurately identify the chain’s grade type. This attention to detail guarantees the reliability and safety of our chain in any application.

Unmatched Durability: Engineered with precision, our Grade 100 chain offers exceptional tensile strength and wear resistance, ensuring long-lasting performance even in the harshest environments.

Enhanced Safety: Each link is meticulously stamped and tested to meet rigorous safety standards, providing peace of mind and reliability for critical lifting operations.

Superior Versatility: VGD’s VQ Grade 100 Chain is compatible with a wide range of lifting and rigging applications, making it a versatile and essential component for any industrial toolkit.

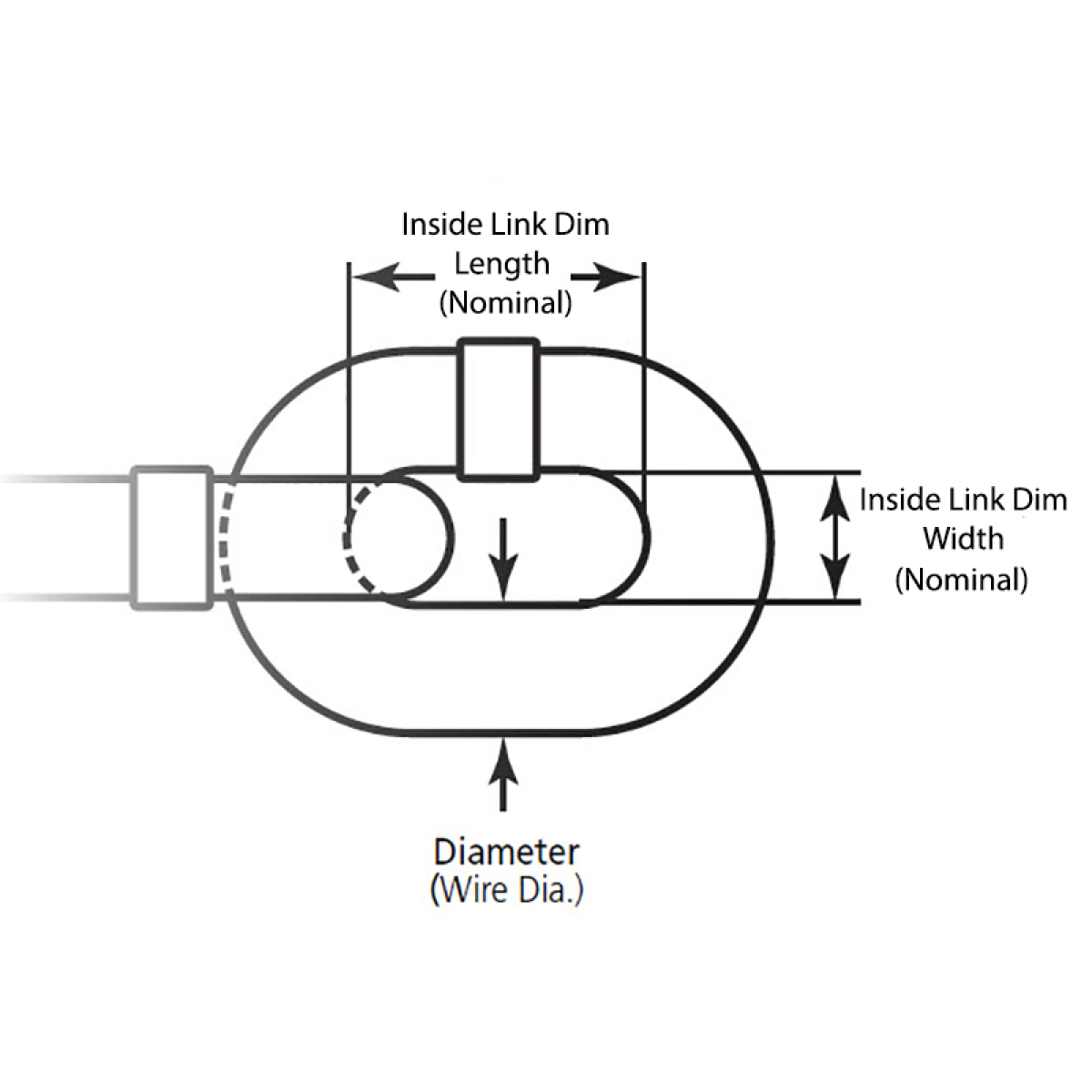

| NOMINAL CHAIN SIZE | MATERIAL DIAMETER | WORKING LOAD LIMIT (MAX) | PROOF TEST (MIN) | INSIDE LENGTH | INSIDE WIDTH RANGE | ||

|---|---|---|---|---|---|---|---|

| IN | MM | IN | MM | LBS | LBS | IN | IN |

| 9/32" | 7.0 | .276 | 7.0 | 4,300 | 8,600 | .90 | 0.375-0.430 |

| 5/16" | 8.0 | .315 | 8.0 | 5,700 | 11,400 | 1.04 | 0.430-0.500 |

| 3/8" | 10.0 | 0.394 | 10.0 | 8,800 | 17,600 | 1.26 | 0.512-0.600 |

| 1/2" | 13.0 | 0.512 | 13.0 | 15,000 | 30,000 | 1.64 | 0.688-0.768 |

| 5/8" | 16.0 | 0.630 | 16.0 | 22,600 | 45,200 | 2.02 | 0.812-0.945 |

| 3/4" | 20.0 | 0.787 | 20.0 | 35,300 | 70,600 | 2.52 | 0.984-1.180 |

| 7/8" | 22.0 | 0.866 | 22.0 | 42,700 | 85,400 | 2.77 | 1.080-1.300 |

Other Products

Inspection Considerations for G80 and G100 Alloy Chain Slings

When inspecting G80 and G100 alloy chain slings, it’s crucial to be thorough and meticulous to ensure safety and compliance. Both OSHA and WorkSafeBC mandate regular inspections, with OSHA requiring at least an annual inspection for all slings, and records must be maintained for each inspection. Here are key pointers to guide you through the process:

Adequate Lighting and Space: Ensure you have plenty of light for good visibility and sufficient space to lay out or hang the chain. Measuring the chain’s reach (from bearing point to bearing point) is easier with two people, facilitating accurate measurement and record-keeping.

Identification Tags: According to OSHA regulations, each chain sling must have a permanently attached tag identifying its size, grade, reach, and Working Load Limit (WLL). Additionally, a sling card record may be required to identify the style (SGG, SOS, CO, etc.) if not indicated on the tag. A sling without a tag is considered out of service due to the inability to verify its specifications. It may have been modified or repaired in the field without proper re-tagging, rendering it invalid without the tag.

Verification of Tag Information: Once the chain sling tag is located, measure the chain sling to verify that the size, grade, and reach match the tag’s information. If discrepancies are found, the chain sling should be removed from service. If the information matches, proceed to a conditional inspection to ensure the chain and fittings are suitable for the specified size and grade.

Condition Inspection: Inspect the chain for any twisted, bent, nicked, gouged, or deformed links. Look for signs of excessive wear on the outside of the links and the inside where links join. This is a crucial point for hinge wear. Check for exposure to heat, caustic solutions, and weld spatter, as these can affect the alloy chain and fittings. Ensure all fittings move freely and are not difficult to operate. Stretched or elongated links indicate an overload and are grounds for removal from service. Fittings should also be inspected for the same issues as the chain, including twists, bends, nicks, cracks, cuts, gouges, excessive wear, deformations, and illegible markings.

Criteria for Removal: Twisted or bent fittings, nicks, cracks, cuts, gouges, excessive wear, deformations, heat exposure, and illegible markings are all potential failure points and grounds for removal from service. While OSHA allows some flexibility for hook distortions, it is recommended to remove any bent fittings from service. A bent hook often indicates an overload situation, posing a significant safety risk.

OSHA specifies that:

“The thorough inspection of alloy steel chain slings shall be performed by a competent person designated by the employer and shall include a thorough inspection for wear, defective welds, deformation, and increase in length. Where such defects or deterioration are present, the sling shall be immediately removed from service.”

WorkSafeBC also provides detailed requirements and guidelines for the inspection and use of chain slings and other lifting equipment. Key aspects include ensuring that only trained and certified personnel perform rigging operations, conducting regular inspections to ensure safety, and maintaining proper documentation of inspections and maintenance activities.

Always check your local laws and governing bodies in your region to ensure compliance with all relevant regulations and standards for chain sling inspections.

By adhering to these guidelines and conducting regular inspections, you ensure the safety and reliability of your chain slings, maintaining compliance with OSHA and WorkSafeBC standards and protecting your workforce.

Always check your local laws and governing bodies in your region to ensure compliance with all relevant regulations and standards for chain sling inspections.

Accuracy Disclaimer: While we strive to provide accurate and up-to-date inspection information, please be aware that regulations, standards, and guidelines may change. It is important to verify the information provided by your local governing bodies or relevant authorities to ensure compliance with current regulations and requirements.