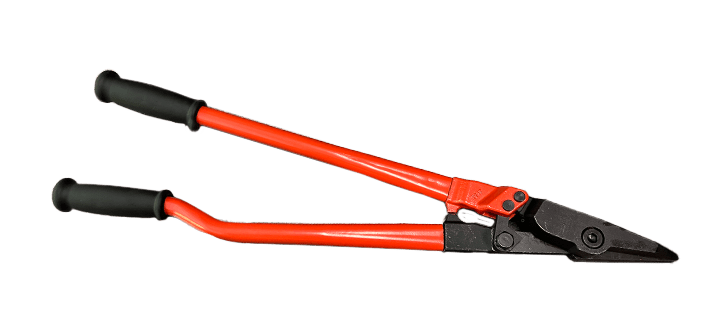

VGD 240 3/8-2" HIGH TENSILE CUTTER

VGD 240 3/8-2" HIGH TENSILE CUTTER

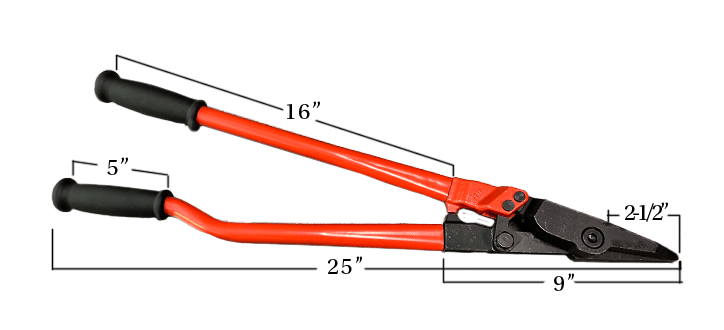

Introducing the VGD 240, a robust and efficient solution for all your steel strapping needs. Designed to handle high tensile steel strapping from 3/8″ up to 2″ in width and up to .005″ in thickness, the VGD 240 is perfect for industrial and commercial applications requiring precision and durability.

Capable of cutting steel strapping from 3/8" to 2" wide and up to .005" thick.

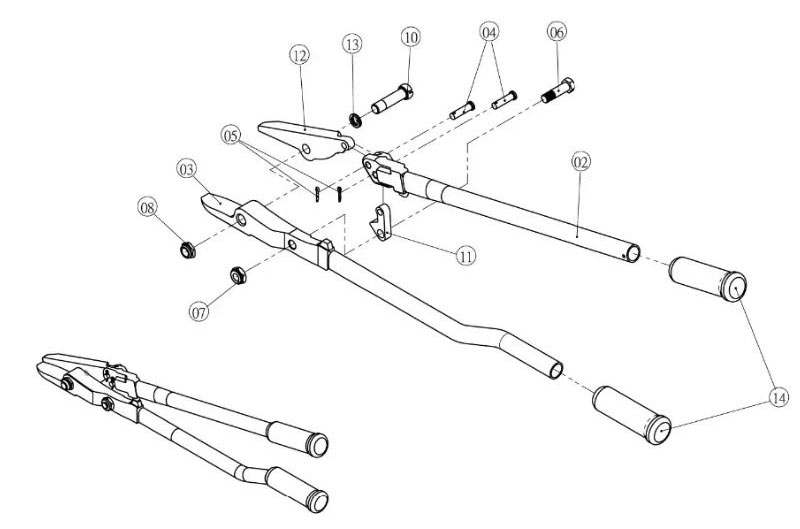

SAE 4140 high carbon steel drop forged

Remove cotter pin to replace the blade

Key Features:

- Versatile Cutting Range: Capable of cutting steel strapping from 3/8″ to 2″ wide and up to .005″ thick.

- High Tensile Strength: Engineered to handle the toughest materials with ease, ensuring clean and precise cuts every time.

- Ergonomic Design: The VGD 240 features an ergonomic handle for comfortable and safe operation, reducing hand fatigue during extended use.

- Durable Construction: Built with high-quality materials to withstand heavy-duty use in demanding environments.

- Safety Mechanisms: Equipped with safety features to protect the user from accidental injuries while cutting.

Applications:

The VGD 240 is ideal for various industries, including shipping, construction, manufacturing, and logistics. Whether you’re securing heavy loads, bundling materials, or preparing shipments, this cutter delivers reliable performance and ensures your operations run smoothly.

Why Choose the VGD 240?

Choosing the VGD 240 means investing in a tool that combines strength, precision, and user-friendly design. Its ability to handle a wide range of strapping sizes and thicknesses makes it a versatile addition to any toolkit, providing unmatched efficiency and safety.

Equip your team with the VGD 240 High Tensile Steel Strapping Cutter and experience the difference in quality and performance.

Maintenance Guide for the VGD 240 High Tensile Steel Strapping Cutter

Proper maintenance of your VGD 240 High Tensile Steel Strapping Cutter ensures its longevity and optimal performance. Follow these maintenance steps to keep your cutter in excellent condition:

1. Regular Cleaning:

- After Each Use: Wipe down the cutter with a clean, dry cloth to remove any debris, dirt, or residual steel particles.

- Weekly: Use a mild detergent and warm water to clean the cutter. Ensure all moving parts are free from grime. Dry thoroughly to prevent rust.

2. Lubrication:

- Monthly: Apply a light machine oil to the pivot points and cutting blades. This reduces friction and ensures smooth operation.

- Check for Overlubrication: Wipe off any excess oil to prevent the accumulation of dust and debris.

3. Blade Inspection:

- Weekly: Inspect the cutting blades for signs of wear, nicks, or dullness.

- Sharpening: If the blades become dull, sharpen them using a fine file or sharpening stone. Replace blades if they are excessively worn or damaged.

4. Safety Check:

- Monthly: Check all safety features, including the blade guards and locking mechanisms, to ensure they are functioning correctly.

- Before Each Use: Ensure the cutter is in proper working condition. Do not use if any parts are loose or damaged.

5. Storage:

- Dry Environment: Store the cutter in a dry place to prevent rust and corrosion.

- Protective Case: Use a protective case or cover to safeguard the cutter from dust and physical damage when not in use.

6. Professional Servicing:

- Annually: Have the cutter professionally serviced at least once a year to ensure all components are in top working condition.

By following these maintenance steps, you can ensure that your VGD 240 High Tensile Steel Strapping Cutter remains reliable and efficient for all your steel strapping needs.

Other Products

Always check your local laws and governing bodies in your region to ensure compliance with all relevant regulations and standards.

Accuracy Disclaimer: While we strive to provide accurate and up-to-date inspection information, please be aware that regulations, standards, and guidelines may change. It is important to verify the information provided by your local governing bodies or relevant authorities to ensure compliance with current regulations and requirements.