VQ Polyester L-Series

ROUND Lifting Slings

A Superior Choice for Safe and Efficient Lifting

VQ Polyester L-Series web round slings offer a premium solution for your lifting needs. Crafted with precision and designed for durability, these slings are engineered to exceed industry standards.

Key Features:

- Individually Proof Tested and Certified: Each VQ Polyester L-Series sling undergoes rigorous individual proof testing to ensure it meets or exceeds industry standards. A certificate of proof test is included with every sling package, providing peace of mind and compliance with safety regulations.

- Durable Leather ID Tags: For easy identification and traceability, each sling is equipped with a durable leather ID tag that resists wear and tear, ensuring long-lasting performance.

- Reduced Stretch: Experience precise lifting with minimal stretch, even under heavy loads. This feature is particularly beneficial when using multiple slings in tandem.

- Water Repellent: Our L-Series slings are designed to withstand harsh conditions. The water-repellent coating helps prevent mildew and grit buildup, extending the sling’s lifespan.

Why Choose VQ Polyester L-Series Slings?

- Safety First: Our commitment to safety is unwavering. Each sling undergoes rigorous testing to ensure it meets or exceeds industry standards.

- Precision Engineering: Our meticulous attention to detail guarantees optimal performance and reliability.

- Our VQ Polyester L-Series slings feature protective gray covers on the load-bearing points for added durability and longevity. These covers shield the sling material from abrasion, wear, and other forms of damage, extending the overall lifespan of the sling and ensuring consistent performance.

When Selecting a Web Sling, Consider These Factors:

- Company Reputation: Choose a reputable manufacturer with a proven track record of quality and safety.

- Webbing Thickness: Ensure the webbing thickness is adequate for your specific lifting requirements.

- Stretch Value: A low stretch value is essential for accurate and controlled lifting.

- Stitching Patterns: Consistent and well-executed stitching patterns contribute to overall sling strength and durability.

- Tag Quality and Attachment: Durable tags securely attached to the sling provide essential information and traceability.

Choose VQ Polyester L-Series Slings for:

- General Lifting Applications

- Machinery and Equipment Handling

- Construction and Industrial Use

Trust VQ for Safe and Reliable Lifting Solutions.

VQ Polyester Lifting Slings - L Series

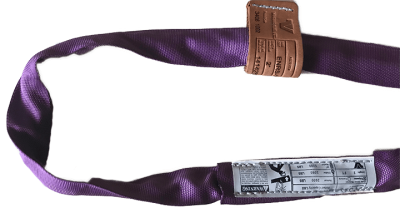

Introducing the VQ L-Series Polyester Round Slings – your ultimate rigging solution. What sets these slings apart is the inclusion of FREE SLIP LEATHER tags, offering numerous benefits for rigging applications. These tags feature a standard plastic safety tag with essential information imprinted for added safety assurance. Additionally, an extra ‘Free Slip’ leather tag carries the same crucial information, ensuring visibility from any angle, regardless of how the sling is positioned.

Notably, the leather safety tag offers exceptional durability, resisting cracks and wear, ultimately extending the service life of the sling.

Our L-Series Round Slings are crafted from polyester yarn, forming a continuous loop enclosed within a polyester fabric sleeve. This sleeve is thoughtfully colour-coded to facilitate the identification of working load capacities, making your rigging tasks more efficient. Furthermore, the construction of the sleeve is designed to safeguard the internal rows of yarn filaments, maintaining their parallel alignment throughout use. This minimizes the risk of ‘load bounce’ during lifting, thanks to the low stretch characteristics of polyester yarn.

What’s more, the VQ L-Series round slings are impressively lightweight and flexible, making them ideal for handling delicate and fragile loads with ease and precision. Whether you’re dealing with heavy-duty rigging or intricate lifting, these slings offer a reliable and versatile solution.

And they are also individually Proof- Tested for added peace of mind.

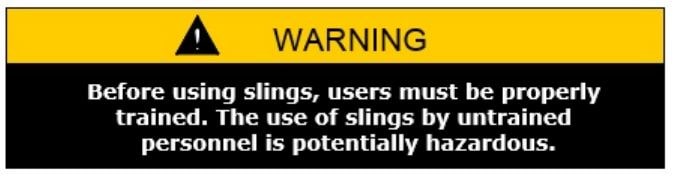

Web Sling & Tie Down Association

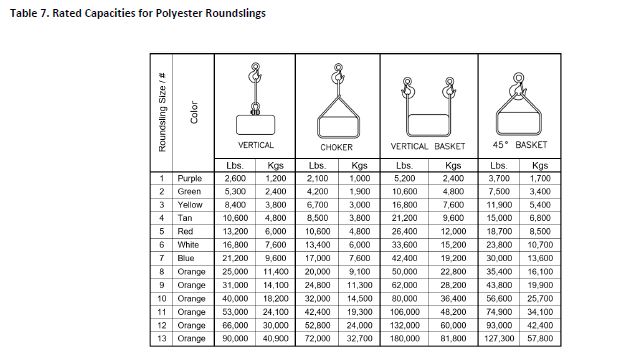

Section 5.1 Roundsling Rated Capacities

Be sure the roundsling you intend to use has an adequate rated capacity for the job (refer to identification and

capacity tag on each sling).

| Round Slings | ||||

| Vertical | Product Codes | |||

| WLL | ||||

| Purple | 2,600 | 340610xx | ||

| Green | 5,300 | 340620xx | ||

| Yellow | 8,400 | 340630xx | ||

| Tan | 10,600 | 340640xx | ||

| Red | 13,200 | 340650xx | ||

| White | 17,000 | 340660xx | ||

| Blue | 21,200 | 340670xx | ||

| Orange | 25,000 | 340680xx | ||

| Gray | 31,000 | 340690xx | ||

| Orange | 40,000 | 340601xx | ||

| Brown | 53,000 | 340611xx | ||

| Olive | 66,000 | 340612xx | ||

| Black | 90,000 | 340613xx | ||

| FX | 5,300 | 340620xxx | ||

Caution: Color codes and rated capacities may vary among manufacturers. ALWAYS CHECK THE IDENTIFICATION TAG TO DETERMINE IF THE POLYESTER ROUNDSLING RATED CAPACITY IS APPLICABLE FOR THE LIFT.

Our slings conform to WSTDA and ASME B30.9

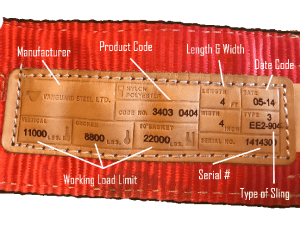

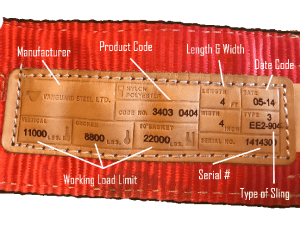

Free Slip Safety Tag

Understanding Sling Types and Tag info

L – Series

The leather safety tag doesn’t crack or wear like the plastic ones giving you longer service life.

- Manufacturer

- Product Code

- Length & Width

- Date Code

- Working Load Limit

- Serial Number

- Type of Sling

UV Exposure and Service Life of VQ L-Series & E-series Slings

Like all synthetic fiber slings, VQ L&E-Series slings are susceptible to degradation when exposed to prolonged UV radiation. This exposure can weaken the material over time, compromising the sling’s strength and safety.

To ensure the longevity and safety of your VQ L&E-Series slings, consider the following:

- Regular Inspection: Conduct frequent inspections for signs of wear, damage, or UV degradation, such as discoloration, cracking, or stiffness.

- Proof Testing: For slings regularly exposed to UV radiation, periodic proof testing to twice their rated capacity can help identify potential issues early on.

- Storage: When not in use, store slings in a cool, dry, and shaded location to minimize UV exposure.

By following these guidelines, you can maximize the service life of your VQ L&E-Series slings and maintain a safe working environment.

What is a Polyester Lifting Slings?

Polyester lifting slings are essential tools used in various industries to safely lift and transport heavy loads. They are favored for their durability, flexibility, and resistance to chemicals and moisture.

Common Applications of Polyester Lifting Slings:

- Construction: Lifting and positioning heavy construction materials like steel beams, concrete slabs, and machinery.

- Manufacturing: Transporting raw materials, finished products, and heavy equipment within factories and warehouses.

- Logistics and Shipping: Securely lifting and moving pallets, crates, and other cargo during loading and unloading operations.

- Oil and Gas: Lifting and transporting heavy equipment and pipelines in harsh environments.

- Mining: Handling large mining equipment and extracted materials.

By using polyester lifting slings, businesses can ensure the safety of their workers and the integrity of their products. It’s crucial to select the appropriate sling for the specific load and lifting conditions to prevent accidents and maximize efficiency

REMOVAL CRITERIA

- A web sling shall be removed from service if any the following forms are visible:

- If web sling identification tag is missing or not readable.

- Holes, tears, cuts, snags or embedded particles in the webbing.

- Broken or worn stitches in load bearing splice.

- Excessive abrasive wear or crushed webbing.

- Knots in any part of the webbing.

- Distortion, excessive pitting, corrosion or damage of any fitting or component.

- Melting, charring or weld spatter on any part of the webbing.

- Acid or alkali burns.

- Any conditions which cause doubts as to the strength of the web sling

Exploring Lifting Slings: Key Queries Answered

What is a Polyester Lifting Sling?

A polyester lifting sling is a durable, flexible strap made from high-quality polyester fibers. It’s designed to safely lift and transport heavy loads in various industries. These slings are known for their strength, durability, and resistance to chemicals and moisture.

Why Choose Polyester Lifting Slings?

- Durability: Polyester slings are highly resistant to abrasion, tearing, and other forms of wear and tear.

- Flexibility: They can be easily maneuvered around awkward shapes and tight spaces.

- Chemical Resistance: Polyester slings are resistant to many chemicals, making them suitable for a wide range of applications.

- Moisture Resistance: They can withstand exposure to moisture without compromising their strength or performance.

Key Factors to Consider When Choosing a Polyester Lifting Sling:

- Working Load Limit (WLL): This is the maximum weight a sling can safely lift. Always ensure the WLL is higher than the weight of the load.

- Sling Type: Different sling types (e.g., round, flat, endless) are suitable for specific applications.

- Sling Length: The length should be appropriate for the lifting task.

- Sling Angle: The angle at which the sling is used can affect its load-bearing capacity.

- Inspection and Maintenance: Regular inspection and maintenance are crucial to ensure the sling’s safety and longevity.

Safe Practices for Using Polyester Lifting Slings:

- Inspect the sling before each use: Check for damage, wear, and fraying.

- Avoid overloading the sling: Always stay within the WLL.

- Properly attach the sling to the load and lifting equipment: Use appropriate hardware and techniques.

- Avoid sharp edges: Protect the sling from contact with sharp objects.

- Store slings properly: Store them in a cool, dry place, away from direct sunlight and extreme temperatures.

By following these guidelines and choosing the right polyester lifting sling for your specific needs, you can ensure safe and efficient material handling operations.

ASTM and WorkSafeBC Requirements for Lifting Sling Inspection

ASTM Standards:

ASTM International (ASTM) provides specific standards for the manufacturing, testing, and inspection of lifting slings. While they don’t dictate inspection frequencies, they provide guidelines for:

- Material specifications: Ensuring the use of appropriate materials for the intended load capacity.

- Manufacturing processes: Guaranteeing proper construction and assembly techniques.

- Performance testing: Verifying the sling’s strength, durability, and resistance to various factors.

WorkSafeBC Requirements:

WorkSafeBC, the British Columbia workplace safety authority, mandates regular inspection and maintenance of lifting equipment, including slings. The specific frequency of inspections may vary depending on factors like usage, environmental conditions, and manufacturer’s recommendations. However, general guidelines include:

- Daily pre-use inspections: Visual checks for damage, wear, and defects.

- Periodic thorough inspections: More detailed examinations conducted by qualified personnel. This might include:

- Checking for signs of wear, such as fraying, cuts, or burns.

- Examining stitching and hardware for damage.

- Verifying the sling’s identification markings, including the manufacturer’s name, WLL, and date of manufacture.

- Conducting load tests, if necessary, to ensure the sling’s capacity

Key Inspection Points for Polyester Lifting Slings:

- General condition: Look for signs of wear, damage, or deterioration.

- Stitching: Check for loose threads, broken stitches, or damaged stitching.

- Webbing: Inspect for cuts, tears, or excessive wear.

- Hardware: Examine hooks, rings, and other fittings for cracks, bending, or distortion.

- Identification markings: Verify that the sling is properly marked with its WLL and other relevant information.

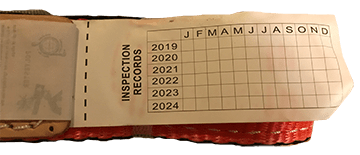

Record Keeping:

WorkSafeBC requires employers to maintain records of inspections and maintenance. These records should include:

- Date of inspection

- Inspector’s name and qualifications

- Findings of the inspection

- Any repairs or replacements made

- Date of the next scheduled inspection

By adhering to ASTM standards and WorkSafeBC regulations, businesses can ensure the safety and reliability of their lifting operations. Regular inspections and maintenance of lifting slings are essential to prevent accidents and protect workers.

Note: Specific inspection requirements may vary depending on local regulations and industry standards. Always consult with local safety authorities and refer to the manufacturer’s guidelines for detailed inspection procedures.

Our factory is: ISO 9001:2015 Certified and a member of LEEA (Lifting Equipment Engineers Association)

Inspection requirements

ASME B30.9 Standards of Inspection on Synthetic Web Slings

Web Sling Inspections and Frequency

All inspections shall be performed by a designated person with any deficiencies further examined by a qualified person to identify hazards and determine what additional steps need to be taken to address the hazard.

ASME B30.9.

Initial Inspection (prior to initial use)

Under best practice it is important to inspect the synthetic web sling to make sure it is what you ordered. The ratings and tags are correct and record the serial number in your log book.

(Written records are not required for initial inspection)

Frequent (daily or prior to use)

Designate a Competent Person* to perform a daily visual inspection of slings and all fastenings and attachments for damage as laid out in the removal section. The inspector should also make sure that the web sling that was selected meets the specific job requirements it’s being used for.

*Competent Person- as laid out in ASME B30.9

A Once-a-day inspection might not be enough if the sling is used multiple times throughout the day under extreme conditions. Shock loads, sharp edges, excessive heat etc. can quickly damage the integrity of the web sling so you will need to develop a ‘best practice’ guideline for your working condition.

(Written records are not required for frequent inspection, however, a ‘best practice’ guideline should be in place)

Periodic Inspection

A periodic inspection shall be performed by a Qualified Person no later than 1 year (at a minimum) More frequent in severe service conditions. The following are all determining factors in scheduling the frequency of a periodic inspection:

Frequency of use

Severity of service conditions

Nature of the lifts being performed

Experience gained on the service life of web slings used in similar applications

ASME provides these additional periodic inspection guidelines based on the service of the synthetic web sling:

Normal Service – Yearly

Severe Service – Monthly to Quarterly

Special Service – As recommended by a Qualified Person

Depending on the severity of the operating environment and frequency of use, your business may decide that a more thorough sling inspection should occur more often than the minimum yearly requirement.

Periodic inspections are required to be documented per ASME B30.9 and record retained. The employer is required to maintain a record of the most recent thorough inspection—however, individual records for each sling that was inspected are not required. Maintaining a ‘best practice’ strategy for recording your slings and which ones have been inspected should make producing records in the event of an accident.

Per ASME B30.9, each synthetic web sling shall be marked by the manufacturer to include:

- Name or trademark of the manufacturer, or if repaired, the entity performing the repair

- Manufacturer’s code or stock number

- Rated load for at least one hitch type and the angle at which it is based

- Type of synthetic web material

- Number of legs, if more than one

It is the responsibility of the user to maintain the sling identification—ensuring the tag or identification is still in place and is still legible during the life of the sling. If the identification tag is missing or illegible, it is the responsibility of the inspector to remove the sling from service.

Basic Inspection Criteria for Synthetic Web Slings

When inspecting web slings, daily visual inspections are intended to detect serious damage or deterioration which would weaken the strength and integrity of the sling.

This inspection is usually performed by the person using the sling in a day-to-day job. If during any point of the inspection the following is observed, the web sling should be removed from service and be discarded:

- Missing or illegible sling identification

- Acid or caustic burns

- Melting or charring of any part of the sling

- Holes, tears, cuts, or snags

- Broken or worn stitching in load-bearing splices

- Excessive wear or abrasion

- Knots in any part of the sling

- Discoloration and brittle or stiff areas on any part of the sling, which may indicate chemical or UV damage

- Fittings that are pitted, corroded, cracked, bent, twisted, gouged, or broken

- For hooks, removal criteria as stated in ASME B30.10

- For rigging hardware, removal criteria as stated in ASME B30.26

- Other conditions, including visible damage, that cause doubt to the continued use of the sling

ASME B30.9 standards specify that a synthetic web sling shall be removed from service immediately if any of the following conditions are present: