8620

(Brown)AISI /SAE 8620 (UNS G 86200)

NICKEL-CHROMIUM-MOLYBDENUM CASE HARDENING STEEL

Size Range

3/4″ – 18″

TYPICAL APPLICATIONS

CARBURIZED SPLINED SHAFTS, PISTON PINS, CAM SHAFTS, GUIDE PINS, BUSHINGS AUTOMOTIVE DIFFERENTIAL PINIONS AND TRANSMISSIONS, ARBORS, BEARINGS, SLEEVES KING PINS, CARBURIZED GEARS, GENERAL ENGINEERING PURPOSES.

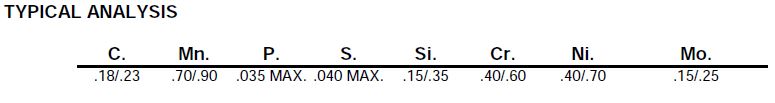

AN ALLOY STEEL DESIGNED FOR CASE HARDENING APPLICATIONS. THE NICKEL IMPORTS GOOD TOUGHNESS AND DUCTILITY. THE CHROMIUM AND MOLYBDENUM CONTRIBUTE INCREASED HARDNESS PENETRATION AND WEAR, THAT MAY BE CARBURIZED. THE WELL BALANCED ALLOY CONTENT PERMITS HARDENING TO PRODUCE A HARD WEAR RESISTANT CASE COMBINED WITH A CORE STRENGTH IN THE ORDER OF 125,000 PSI. IT HAS EXCELLENT MACHINABILITY AND RESPONDS WELL TO POLISHING APPLICATIONS. WITH THE BALANCED ANALYSIS, THIS STEEL PROVIDES, UNIFORM CASE DEPTH, HARDNESS AND WEAR PROPERTIES, AND GIVES THE ADVANTAGE OF LOW DISTORTION.