Premium Golden Eye Wire Rope Slings

Premium Golden Eye Wire Rope Slings:

Strong, Reliable, and Certified

Introducing our premium Golden Eye wire rope slings, designed to provide reliable and secure lifting solutions for various applications. These slings are distinguished by their high-quality construction and unique features, including a signature golden-coloured strand woven into the wire rope for easy identification.

In lifting operations, it can be challenging to ensure the safety and reliability of wire rope slings, especially when identifying specific slings or verifying their quality. Without clear markings or unique identifiers, selecting the right sling for the job can be a daunting task.

Our premium Golden Eye wire rope slings address these challenges by incorporating a signature golden-coloured strand woven into the wire rope. This distinctive feature serves as a visual identifier, making it easy to differentiate between slings and ensuring that the right sling is selected for each lifting task. Additionally, each sling comes with a safety tag and certificates, providing essential information about the sling’s specifications and compliance with safety standards.

EYE AND EYE MECHANICALLY PRESSED FLEMISH SLEEVES

VGD - Wire rope slings - SOFT EYES

These premade wire rope slings are an economical option and have the following qualities that often exceed their counterpart.

better at abrasion resistance than synthetic web and round sling.

Often cheaper than Chain Slings and fit snugly in a choker hitch, keeping the load secure.

Quick to notice flaws or damage to a wire rope sling than a chain sling.

Lighter than a chain sling of comparable working load limit.

Wire rope slings are a type of lifting device used to lift and move heavy loads. They consist of a length of wire rope, which is made up of several smaller wires twisted together, and a fitting or attachment at each end that allows the sling to be connected to a crane, hoist, or other lifting equipment. The wire rope is flexible and strong and can be used to lift a wide range of loads, including heavy machinery, containers, and other large items.

Additionally, our signature golden-colored strand woven into the wire rope serves as a unique identifier, guaranteeing the authenticity and quality of our slings. Each sling is also equipped with a safety tag, highlighting important information such as safe working load limits and inspection dates, ensuring that your lifting operations are conducted with the highest standards of safety and compliance.

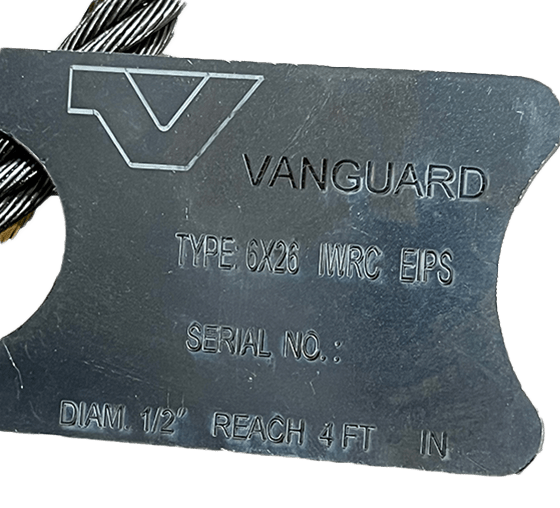

Safety Tag

Brand

Type

Serial number

WLL

Precision swaged compression collar

Signature gold wire strand for brand recognition

Our wire rope slings feature quality Flemish pressed sleeves, ensuring strong and reliable connections that withstand the rigors of lifting operations. The sleeves are mechanically pressed to create a secure bond between the wire rope strands, providing added durability and safety.

Additionally, our signature golden-colored strand woven into the wire rope serves as a unique identifier, guaranteeing the authenticity and quality of our slings. This golden strand is a mark of our commitment to excellence and distinguishes our slings from others in the market.

Each sling is also equipped with a safety tag, highlighting important information such as safe working load limits and inspection dates. This ensures that your lifting operations are conducted with the highest standards of safety and compliance.

Type of sling details

Size and length of the sling

Brand logo and manufacture of sling

Serial Number

Each of our wire rope slings comes with a safety tag attached, providing essential information such as safe working load limits and inspection dates. This tag ensures that operators can easily verify the sling’s specifications and safety compliance before each use.

Additionally, our slings feature a stamped manufacturer’s logo, serving as a mark of quality and reliability. This logo indicates that the sling has undergone rigorous testing and meets all relevant industry standards, giving you confidence in its performance.

When it comes to identifying the type of sling, our products are clearly labeled for easy identification. Whether you need a single-leg, double-leg, or multi-leg sling, the type is clearly indicated, ensuring that you select the right sling for your lifting needs.

Furthermore, each sling is assigned a unique serial number, allowing for easy tracking and traceability. This serial number provides important information about the sling’s manufacturing date, materials used, and other relevant details, ensuring accountability and quality control throughout its lifecycle.

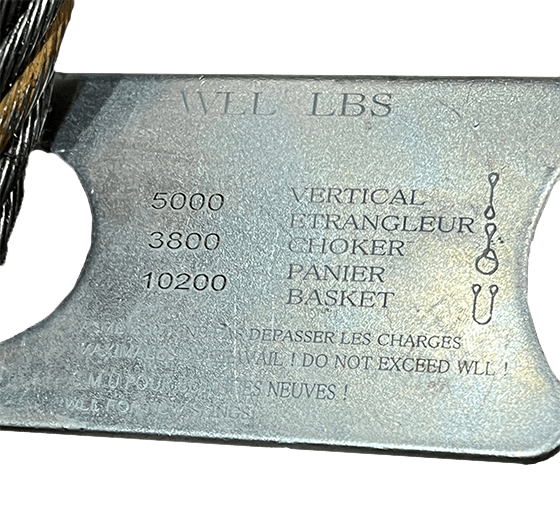

Working Load Limit and unit of measurement (LBS)

Type of lifts

Max weights for each type of lift in LBS

Each safety tag is stamped with the sling’s Working Load Limit (WLL), providing crucial information about the maximum load capacity for safe lifting operations. This ensures that operators can easily determine whether the sling is suitable for the intended load, helping to prevent overloading and maintain safety.

Furthermore, the tag specifies the type of lift for which the sling is rated, whether it is for vertical, choker, or basket lifts. This information is essential for ensuring that the sling is used correctly and in accordance with its design specifications, minimizing the risk of accidents and damage to the load.

By providing clear and concise information on each safety tag, we aim to enhance safety and efficiency in lifting operations, allowing you to confidently use our wire rope slings in a variety of lifting applications.

1/4" to 1" size options

complete with safety tag and certificate

| SIZE | CONSTRUCTION | LENGTH OPTIONS IN FT | VERTICAL LBS | CHOKER LBS | BASKET LBS |

|---|---|---|---|---|---|

| 1/4" | 6X26 IWRC EIPS | 4, 6, 8, 10, 12 | 1,300 | 960 | 2,600 |

| 3/8" | 6X26 IWRC EIPS | 4, 6, 8, 10, 12 | 2,800 | 2,200 | 5,800 |

| 1/2" | 6X26 IWRC EIPS | 4, 6, 8, 10, 12 | 5,000 | 3,800 | 10,200 |

| 5/8" | 6X26 IWRC EIPS | 4, 6, 8, 10, 12 | 7,800 | 5,800 | 15,600 |

| 3/4" | 6X26 IWRC EIPS | 4, 6, 8, 10, 12 | 11,200 | 8,200 | 22,000 |

| 1" | 6X26 IWRC EIPS | 4, 6, 8, 10, 12 | 19,600 | 14,400 | 40,000 |

Understanding VGD Code

W.R.Sling – Size – Length

3202 – XX – XX

First 4 digits are the product class.

Next 2 digits are the diameter of the wire.

Last 2 digits are the length in feet.

Example: 1/4″ x 6ft

3202 – 16 – 06

(32021606)

24=3/8″

32=1/2″

40=5/8″

48=3/4″

56=7/8″

64=1″

WARNING: NEVER EXCEED WORKING LOAD LIMITS!

LOAD RATINGS ARE FOR WIRE ROPE SLINGS IN ‘NEW CONDITION’!

INSPECT LIFTING SLINGS REGULARLY AND REPLACE ALL COMPONENTS SHOWING SIGNS OF WEAR!

VGD Wire Rope Sling Break Test | Vanguard Quality Assurance

Watch as a VGD wire rope sling is pushed to its limits in this controlled breaking test. See the full setup, real-time stress application, and the dramatic moment of failure—demonstrating both the strength of our slings and Vanguard’s uncompromising commitment to safety, reliability, and industry-leading standards.