GRADE 80 LIFTING SWIVEL EYE BOLTS

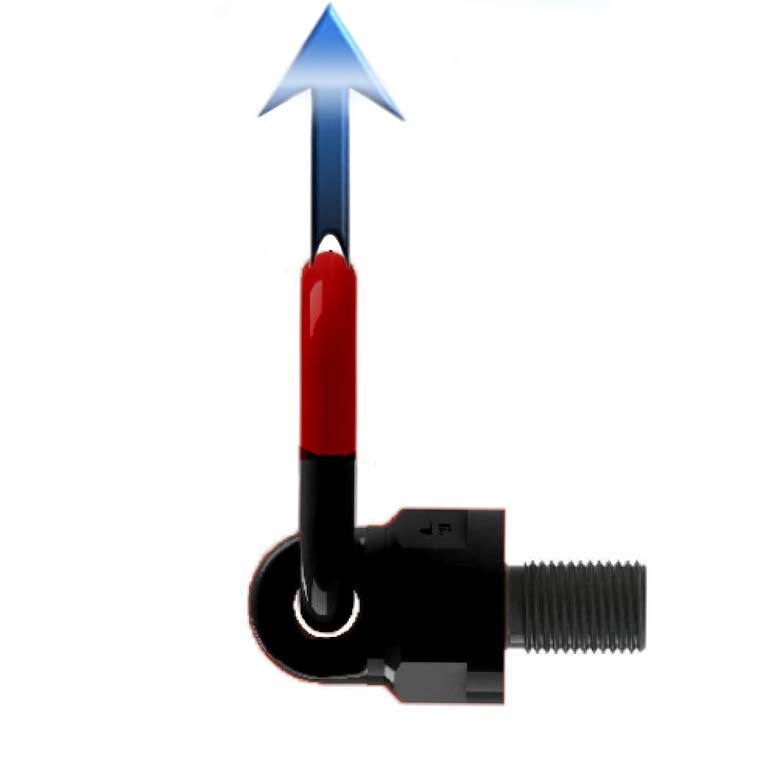

ROTATES UNDER LOAD

Introducing Grade 80 Lifting Swivel Eye Bolts:

Safe, Versatile, and Heavy-Duty

G80

Swivel Ring

Roller Bearing: 360° Rotation Under Load

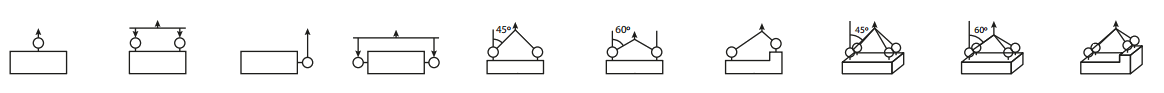

Experience the ultimate in lifting versatility and safety with our Grade 80 Lifting Swivel Eye Bolts. Crafted from heavy-duty, all-steel construction, these innovative bolts are designed to rotate under load, allowing for safe lifting at various angles. Whether you need to lift units from horizontal to vertical or require full rotation of the loop, our swivel lifting eyes pivot 180 degrees and swivel 360 degrees simultaneously, ensuring you can lift from any direction with ease. Available in both inch and metric sizes, these eye bolts are the ideal choice for any lifting application where safety and reliability are paramount.

Safety First: Grade 80 Lifting Swivel Eye Bolts are designed with safety as the top priority, allowing for lifting at various angles without compromising on security. The rotating feature ensures that your lifting operations are both efficient and safe.

Versatile Lifting: These heavy-duty eye bolts enable users to lift units from horizontal to vertical and back again if required. The swivel lifting eye pivots 180+ degrees and swivels 360 degrees simultaneously, providing full rotation and versatile lifting from any direction.

Durable Construction: Made from high-quality steel, these swivel eye bolts are built to last. Their all-steel construction ensures durability and reliability, making them the ideal choice for demanding lifting applications.

As a safety precaution, Normal Eye Bolts are not recommended for Lifting at angles.

90º

Designed WLL at 90º degrees

>180º

Link swivels over 180º degrees

360º

Bearings gives full 360º degrees

Caution

When installing, do not over tighten.

Other Name:

Bolt-On

Swivel Hoist Ring

Swivel Shackle

Grade 80 Rotating Eye Bolt

Inch Size - Black Base

| G-80 Swivel Rings | ||||||||||||||

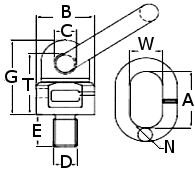

| Tape Size | WLL | Dimensions | Weight | Product | ||||||||||

| (lbs) | (inches) | lbs/pc | Code | |||||||||||

| D | 0 deg. | 90 deg. | A | W | B | C | E | G | T | N | ||||

| 1/4 | – | 20 | 1,213 | 606 | 2.057 | 1.107 | 1.428 | 0.677 | 0.512 | 2.109 | 1.770 | 0.54 | 0.90 | 297811613 |

| 5/16 | – | 18 | 1,323 | 661 | 2.076 | 1.130 | 1.427 | 0.694 | 0.512 | 2.078 | 1.727 | 0.55 | 0.92 | 297812013 |

| 3/8 | – | 16 | 1,984 | 1,102 | 2.089 | 1.134 | 1.424 | 0.643 | 0.709 | 2.076 | 1.767 | 0.56 | 0.95 | 297812418 |

| 7/16″ | – | 14 | 2,205 | 1,102 | 2.078 | 1.158 | 1.428 | 0.645 | 0.709 | 2.102 | 1.722 | 0.55 | 0.96 | 297812818 |

| 1/2″ | – | 13 | 2,205 | 1,102 | 2.068 | 1.155 | 1.420 | 0.680 | 0.787 | 2.116 | 1.824 | 0.55 | 0.98 | 297813220 |

| 5/8″ | – | 11 | 4,409 | 2,469 | 2.066 | 1.130 | 1.423 | 0.648 | 0.787 | 2.139 | 1.705 | 0.54 | 1.05 | 297814020 |

| 3/4″ | – | 10 | 8,818 | 4,409 | 2.756 | 1.378 | 1.949 | 0.748 | 1.181 | 2.677 | 2.205 | 0.63 | 2.11 | 297814830 |

| 7/8″ | – | 9 | 11,023 | 5,512 | 2.756 | 1.378 | 1.949 | 0.748 | 1.181 | 2.677 | 2.205 | 0.63 | 2.45 | 297815630 |

| 1″ | – | 8 | 13,889 | 6,945 | 3.363 | 1.575 | 2.374 | 0.866 | 1.181 | 3.202 | 2.727 | 0.71 | 3.11 | 297816430 |

| 1-1/4″ | – | 7 | 26,015 | 17,637 | 4.541 | 1.969 | 3.159 | 1.063 | 1.969 | 4.344 | 3.554 | 0.87 | 8.00 | 297818050 |

Metric Size - Red Base

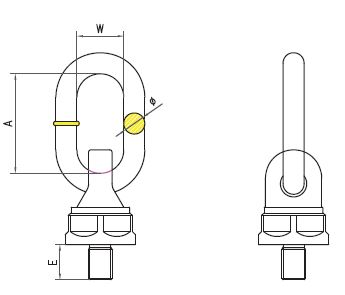

| Tap Size | Dimensions (mm) | WLL at Lift Angle (tons) | Weight (lbs/pc) | Vanguard Code | ||||

| A | E | W | Ø | 0 Deg. | 90 Deg. | |||

| M8 | 55 | 13 | 30 | 13 | 0.60 | 0.30 | 0.92 | 2978 20813 |

| M8 | 55 | 18 | 30 | 13 | 0.60 | 0.30 | 0.95 | 2978 20818 |

| M10 | 55 | 18 | 30 | 13 | 0.90 | 0.45 | 0.96 | 2978 21018 |

| M10 | 55 | 25 | 30 | 13 | 0.90 | 0.45 | 1.11 | 2978 21025 |

| M12 | 55 | 20 | 30 | 13 | 1.00 | 0.50 | 1.11 | 2978 21220 |

| M12 | 55 | 27 | 30 | 13 | 1.00 | 0.50 | 1.11 | 2978 21227 |

| M16 | 55 | 24 | 30 | 13 | 2.00 | 1.12 | 1.11 | 2978 21624 |

| M16 | 55 | 30 | 30 | 13 | 2.00 | 1.12 | 1.12 | 2978 21630 |

| M16 | 55 | 35 | 30 | 13 | 2.00 | 1.12 | 1.15 | 2978 21635 |

| M20 | 85 | 30 | 40 | 18 | 4.00 | 2.00 | 2.14 | 2978 22030 |

| M20 | 85 | 43 | 40 | 18 | 4.00 | 2.00 | 2.20 | 2978 22043 |

| M24 | 85 | 30 | 40 | 18 | 6.30 | 3.15 | 3.22 | 2978 22430 |

| M24 | 85 | 38 | 40 | 18 | 6.30 | 3.15 | 3.27 | 2978 22438 |

| M30 | 115 | 35 | 50 | 25 | 10.60 | 5.30 | 4.81 | 2978 23035 |

| M30 | 115 | 50 | 50 | 25 | 11.80 | 8.00 | 8.30 | 2978 23050 |

| M36 | 115 | 54 | 50 | 25 | 11.80 | 8.00 | 8.65 | 2978 23654 |

Installation and maintenance

Installation and Usage Guidelines:

Ensure the eye bolt thread is fully screwed in by using a sufficiently long thread hole.

- Manually screw the eye bolt thread securely and tightly to the contact surface; avoid tightening with tools.

- When lifting vertically, ensure the load is within reach of the loading ring.

- The product can rotate under the rated load but is not suitable for continuous rotation at full load in a 90° direction.

- All operations must strictly adhere to the product operation manual.

Acceptance Procedure:

- Dimensional Acceptance: Ensure compliance with relevant standards, absence of cracks or defects, and a clear indication of specifications, bearing capacity, and material code on the eye bolt surface.

- Thread Acceptance: Visually inspect the thread for intactness and lack of damage. Test using a thread ring gauge (drift diameter gauge, no-go gauge) with an accuracy of 6g.

- Perpendicularity Check: Verify that the thread axis of the eye bolt is perpendicular to the bearing surface. Rotate a go gauge to fit the thread root with the bearing surface without clearance, indicating acceptable perpendicularity.

- Documentation: Provide a certificate of delivery or detailed written test report for archival purposes for all accepted eye bolts.

Operation Restrictions:

- Temperature Range: The operating temperature should be between -40°C to 400°C. For temperatures exceeding 200°C, consult the manufacturer for guidance.

- Chemical Environment: Avoid contact with acid, alkali, or vapours. For applications in chemical environments, contact Vanguard Steel Ltd for guidance.

- Safety Warning: Do not exceed the maximum safe lifting load.

Installation and Operation Precautions:

- Maximum Lifting Weight: The maximum lifting weight (safe working load at limit) of the eye bolt applies only when installed on steel, cast steel, or non-cast iron parts.

- Threaded Hole Area: Keep the area around the threaded hole smooth, and ensure the hole depth is sufficient to fully lock the bolt.

- Proper Installation: Screw the eye bolt in to make the bearing surface fit closely, but do not forcefully tighten it with tools. Failure to screw it in properly may cause deformation or breakage of the eyebolt.

- Lifting Angle: Lift the goods according to the safe working load angle of the eye bolt. Install the eye bolts at different positions based on the specific lifting mode. Avoid moving the center of gravity during lifting.

- Lifting Points: Install the eye bolts according to the number of lifting points designed on the workpiece. Do not reduce the number of lifting points.

- Slow Hoisting: Slowly hoist the goods to avoid impact from fast lifting.

- Prohibited Actions: Do not engage in any illegal operations.

Storage Guidelines:

Vanguard lifting eye bolt products should be stored in a clean, dry place, free from corrosion and oil. Ensure that the threads are well protected from collisions.

Warning:

- Is there a risk of heavy objects falling off during abnormal assembly and hoisting operations?

- Falling heavy objects can cause serious injury or death.

- During installation, and before each use, a visual inspection should be done paying special attention to corrosion, wear, cracks, or deformation.

- Ensure that the thread of the bolt matches the threaded hole.