Swager Hand Tools

HSC 350 Hand Swager (for aluminum oval sleeves) (350mm)

Wire rope dia (mm,inch):

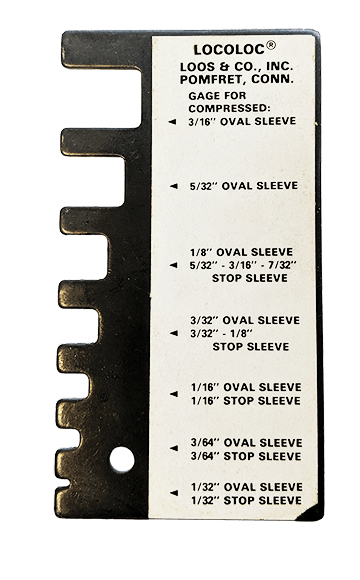

1.5mm - 1/16" | 2mm - 5/64" | 2.5mm - 3/32" | 3mm - 1/8"

Max cutting capacity: 3.5mm - 1/8"

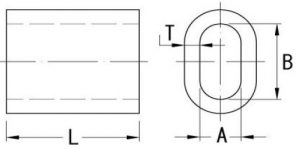

Note: Select appropriate sleeves according to the wire rope diameter used.

| Item No | Part Number | Overall Length mm | Wire Rope Diameter mm - Inch | Weight kg |

|||

|---|---|---|---|---|---|---|---|

| HSC 350 | 3003-1006 | 430 | 1.5mm - 1/16" | 2mm - 5/64" | 2.5mm - 3/32" | 3mm - 1/8" | 1.1 |

HSC 600 Hand Swager (for aluminum oval sleeves) (600mm)

Wire rope dia (mm,inch):

1.5mm - 1/16" | 2mm - 5/64" | 2.5mm - 3/32" | 3mm - 1/8" | 3.5mm | 4mm - 5/32" | 5mm - 3/16"

Max cutting capacity: 5mm - 3/16"

Note: Select appropriate sleeves according to the wire rope diameter used.

| Item No | Part Number | Overall Length mm | Wire Rope Diameter mm - Inch | Weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| HSC 600 | 3003-1002 | 600 | 1.5mm - 1/16" | 2mm - 5/64" | 2.5mm - 3/32" | 3mm - 1/8" | 3.5mm - | 4mm - 5/32" | 5mm - 3/16" | 2.7 |

HS 600B Bench Swager (for aluminum oval sleeves) (540mm)

Suitable for large amount of swaging work

Wire rope dia (mm,inch):

1.5mm - 1/16" | 2mm - 5/64" | 2.5mm - 3/32" | 3mm - 1/8" | 3.5mm | 4mm - 5/32" | 5mm - 3/16"

Max cutting capacity: 5mm - 3/16"

Note: Select appropriate sleeves according to the wire rope diameter used.

| Item No | Part Number | Overall Length mm | Wire Rope Diameter mm - Inch | Weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| HS 600B | 3003-1001 | 540 | 1.5mm - 1/16" | 2mm - 5/64" | 2.5mm - 3/32" | 3mm - 1/8" | 3.5mm - | 4mm - 5/32" | 5mm - 3/16" | 5.2 |