- 1-866-294-3191

- Open Monday to Friday 8am to 5pm

- Emergency Callout Available

Grade 80 Alloy Lifting

VGD Grade 80 lifting rigging features a vibrant red body with sleek black ends, combining safety and style. Crafted from high-strength alloy steel, this rigging chain offers exceptional durability, strength, and reliability for lifting heavy loads in various industries.

Key features include:

High Strength: Manufactured from high-strength alloy steel, VGD Grade 80 lifting rigging ensures safe lifting of heavy loads.

Durability: The alloy steel construction provides exceptional durability, capable of withstanding tough working conditions.

Safety: Designed with safety in mind, the SL rigging features safety hooks and latches to prevent accidental detachment of the load.

Versatility: Suitable for a wide range of lifting applications, from light-duty to heavy-duty lifting tasks.

Compliance: Manufactured to meet or exceed industry standards and regulations for lifting equipment, ensuring it is safe and reliable to use.

VGD Grade 80 lifting rigging is not only a reliable lifting solution but also a visually striking one, with its red body and black ends adding a touch of style to its exceptional performance.

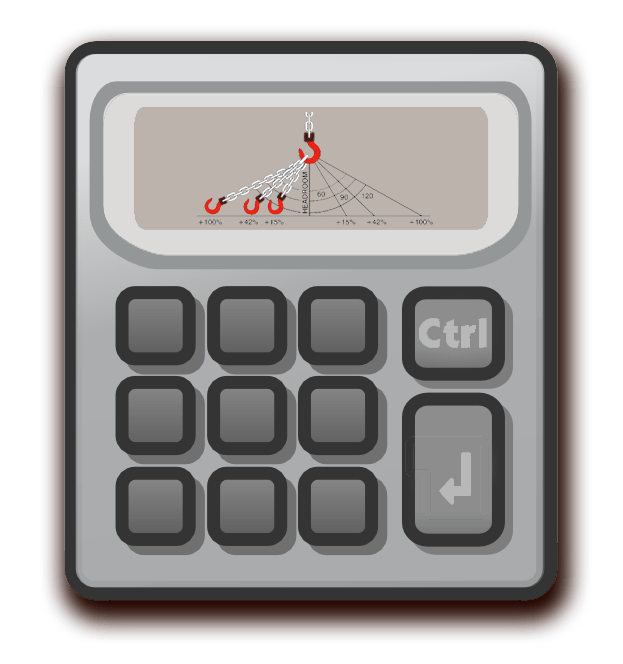

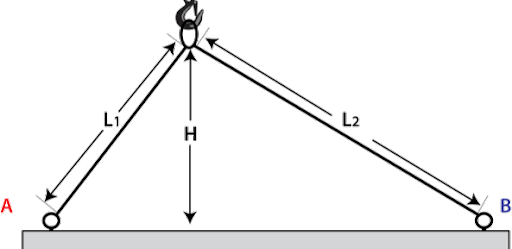

GRADE 80 CHAIN SLING CALCULATOR

*See bottom for detailed instructions on how to use the Chain Sling Calculator

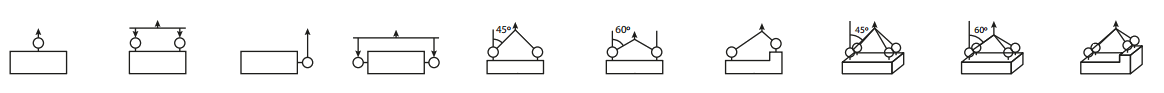

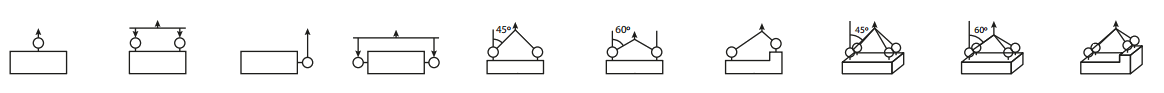

Select the style of chain sling you require

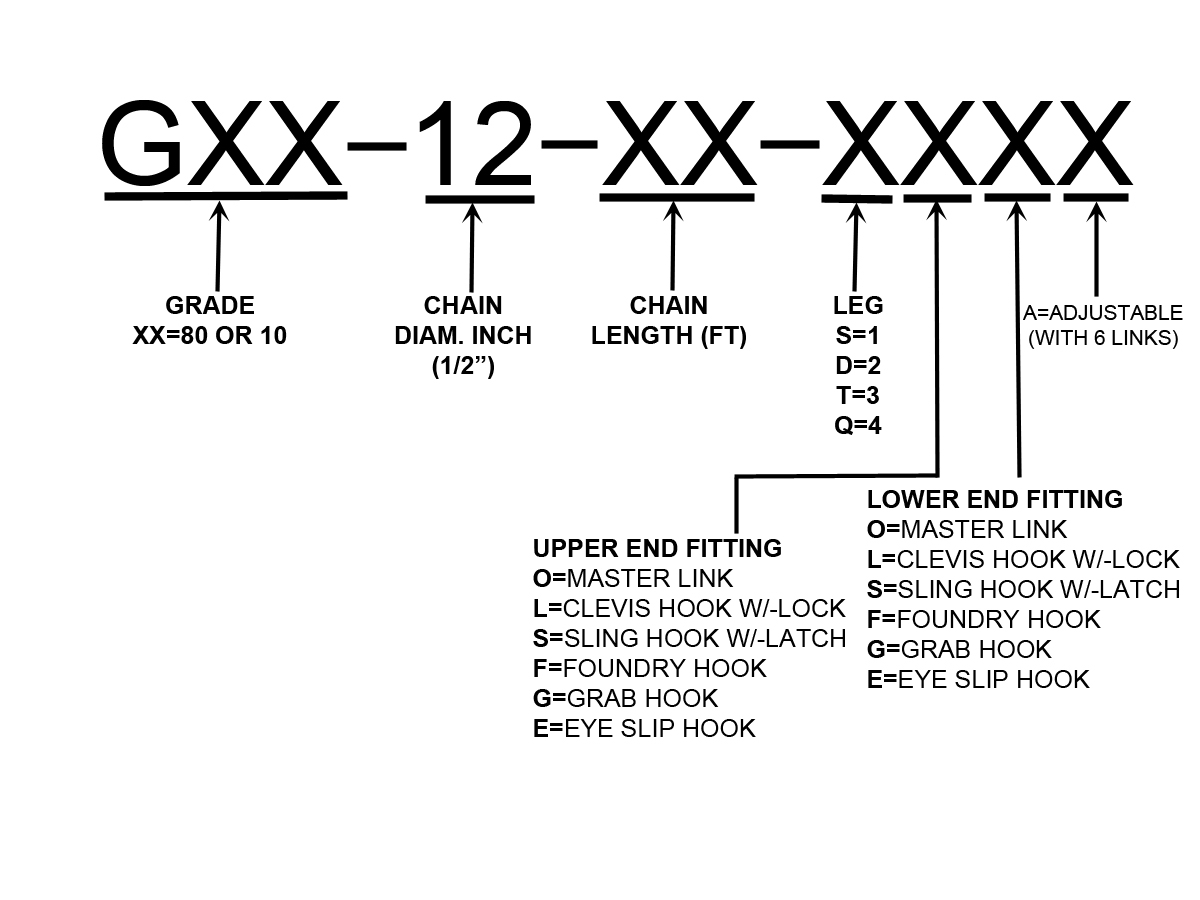

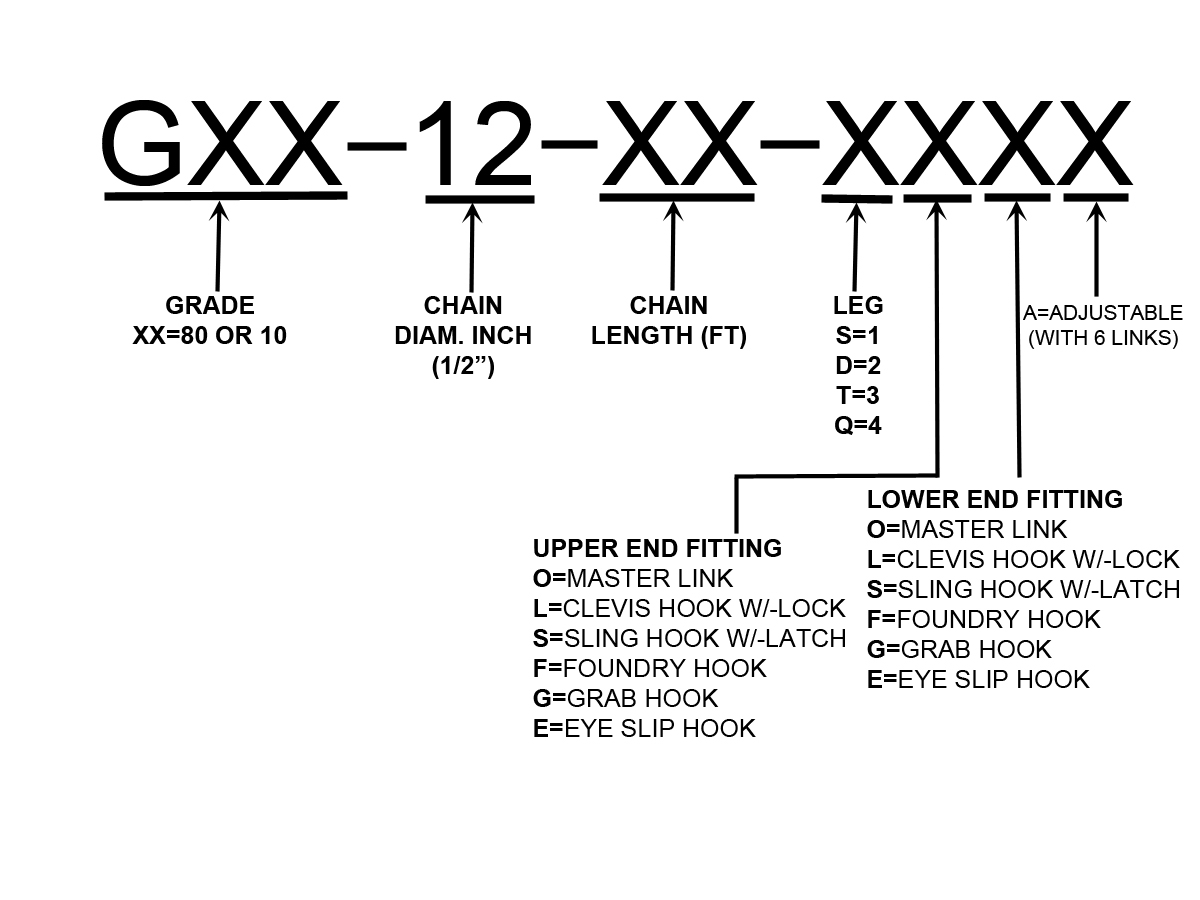

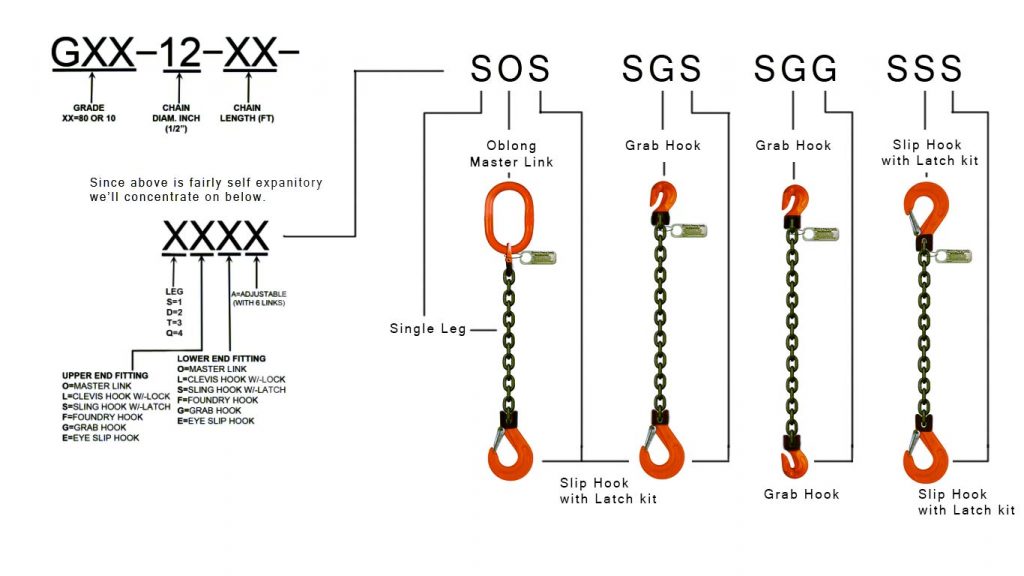

Understanding the description and how to order

1. Select the grade of chain.

2. Select the size of chain based of the load you need to lift.

3. Select the length of the legs you require.

4. Select the number of legs you need.

5. Select upper side of sling.

i.e. “S” single and then “O” Master link or “G” Grab etc…

6. Select lower end fitting.

7. Select if you want to be able to adjust by adding an “A” (sometimes added at the beginning as above diagram)

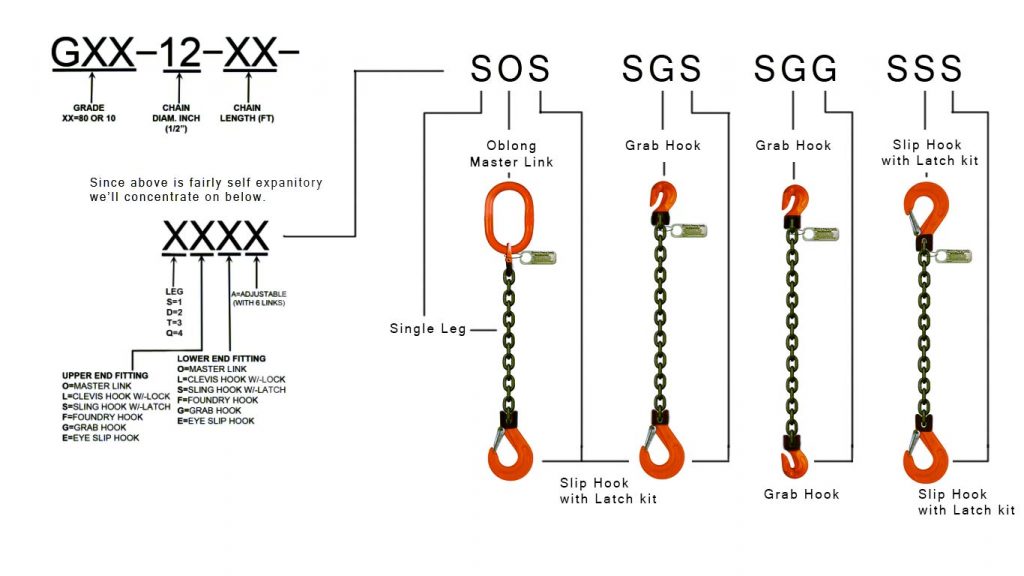

Now that we know how the full description is laid out we are going to concentrate on the last section that gives you legs, end fittings, etc…

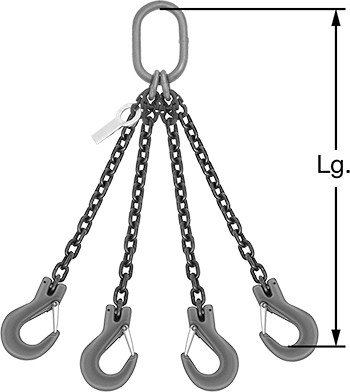

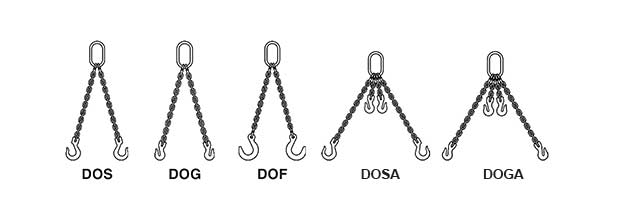

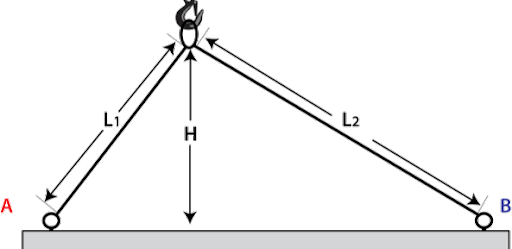

See [image 1]

- SOS = Single-Leg – Oblong Master Link – Slip Hook with Latch Kit

- SGS = Single-Leg – Grab Hook – Slip Hook with Latch Kit

You get the idea. If you need the sling adjustable, simply add the letter “A” at the end. SOSA.

Note: Keep in mind that not all slings can be made adjustable.

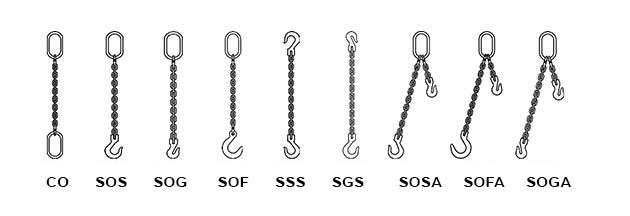

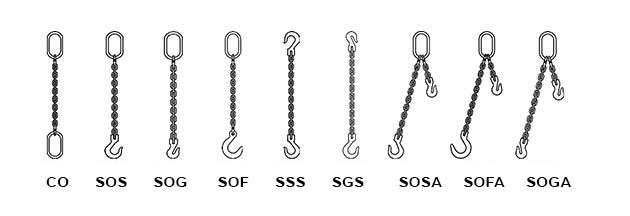

Standard Type Slings

SINGLE LEG

- CO

- SOS

- SOG

- SSS

- SGS

- SOSA

- SOGA

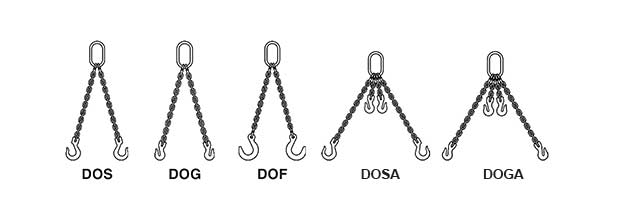

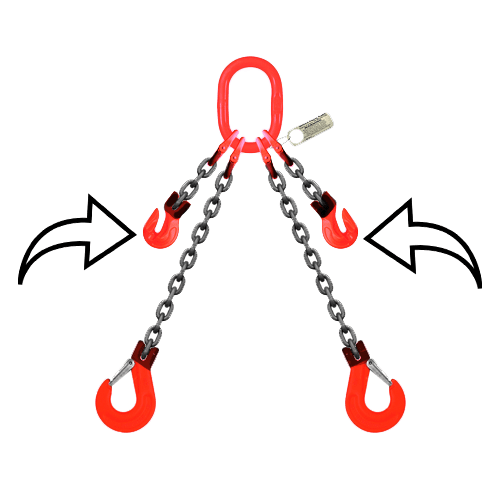

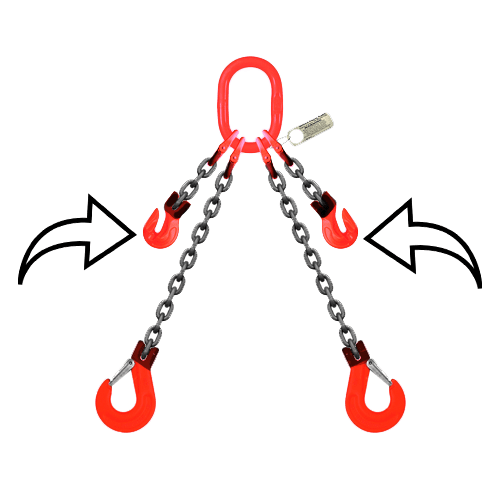

DOUBLE LEG

- DOS

- DOG

- DOSA

- DOGA

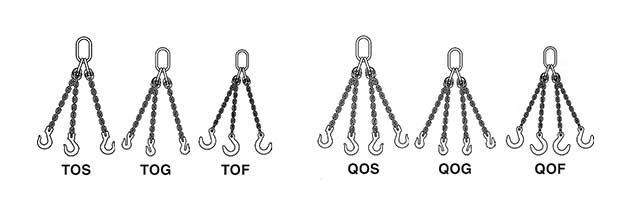

TRIPPLE LEG

- TOS

- TOG

- TOSA

- TOGA

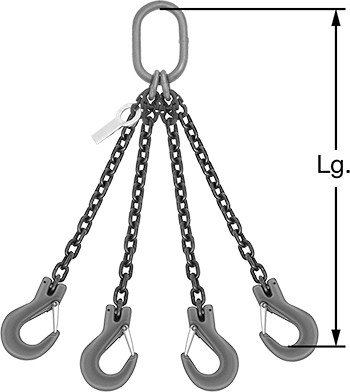

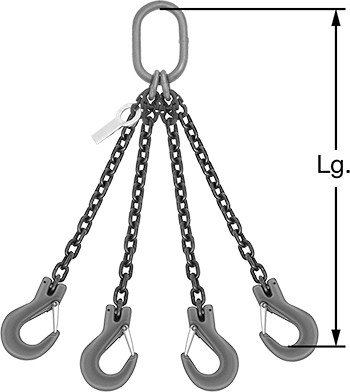

QUAD LEG

- QOS

- QOG

- QOSA

- QOGA

Standard Type of Hooks

Adjustable Style

Grade 80 Weld-on hook

make your lifts safer

These Weld-on bucket hooks are versatile anchor points for general lifting applications. The hook can be welded on without preheating.

Also, they are designed to handle the working load when buckets are tipped forward.

Additionally, they have an integrated latch kit to prevent accidental unhooking while in operation.

Durable powder coated for increased years of service.

- Made of Grade 80 Alloy steel, forged, quenched and tempered

- Features a large weld pad, uncoated for easy welding

- Heavy-duty integrated latch kit

Designed for attachment to mobile lifting equipment to provide a pick point for easy sling attachment.

Features a large weld pad, uncoated for easy welding

Heavy-duty integrated latch kit

1 ton - 10 tons capacity wll

with intigrated spring loaded safety cast latch

| SIZE TON (WLL) | PCS/CARTON | PRODUCT CODE | WEIGHT (LBS/PC) |

|---|---|---|---|

| 1 | 30 | 3951 2010 | 1.08 |

| 2 | 20 | 3951 2020 | 30.28 |

| 3 | 15 | 3951 2030 | 39.54 |

| 5 | 8 | 3951 2050 | 79.82 |

| 8 | 6 | 3951 2080 | 99.80 |

| 10 | 4 | 3951 2100 | 11.50 |

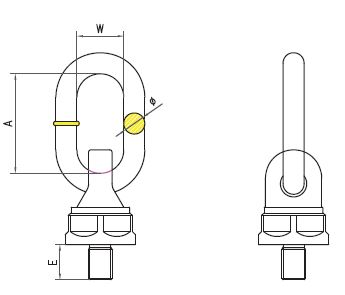

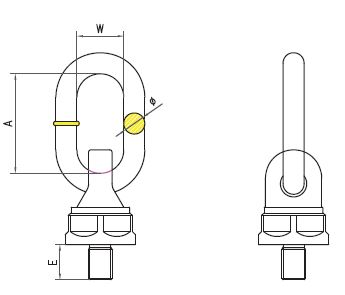

Grade 80 Lifting Swivel Eye Bolts

Rotates under load

As a safety precaution, Normal Eye Bolts are not recommended for Lifting at angles. Made from all steel construction the swivel lifting eye is a heavy duty lifting device which enables the user to safely lift units from horizontal to vertical and back again if required. Swivel Lifting Eyes are used where it is necessary to have full rotation of the loop Pivots 180 degrees and swivels 360 degrees simultaneously to allow lifting from any direction.

Other Name:

Bolt-On

Swivel Hoist Ring

Swivel Shackle

Grade 80 Rotating Eye Bolt

Inch Size - Black Base

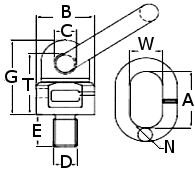

| G-80 Swivel Rings | ||||||||||||||

| Tape Size | WLL | Dimensions | Weight | Product | ||||||||||

| (lbs) | (inches) | lbs/pc | Code | |||||||||||

| D | 0 deg. | 90 deg. | A | W | B | C | E | G | T | N | ||||

| 1/4 | – | 20 | 1,213 | 606 | 2.057 | 1.107 | 1.428 | 0.677 | 0.512 | 2.109 | 1.770 | 0.54 | 0.90 | 297811613 |

| 5/16 | – | 18 | 1,323 | 661 | 2.076 | 1.130 | 1.427 | 0.694 | 0.512 | 2.078 | 1.727 | 0.55 | 0.92 | 297812013 |

| 3/8 | – | 16 | 1,984 | 1,102 | 2.089 | 1.134 | 1.424 | 0.643 | 0.709 | 2.076 | 1.767 | 0.56 | 0.95 | 297812418 |

| 7/16″ | – | 14 | 2,205 | 1,102 | 2.078 | 1.158 | 1.428 | 0.645 | 0.709 | 2.102 | 1.722 | 0.55 | 0.96 | 297812818 |

| 1/2″ | – | 13 | 2,205 | 1,102 | 2.068 | 1.155 | 1.420 | 0.680 | 0.787 | 2.116 | 1.824 | 0.55 | 0.98 | 297813220 |

| 5/8″ | – | 11 | 4,409 | 2,469 | 2.066 | 1.130 | 1.423 | 0.648 | 0.787 | 2.139 | 1.705 | 0.54 | 1.05 | 297814020 |

| 3/4″ | – | 10 | 8,818 | 4,409 | 2.756 | 1.378 | 1.949 | 0.748 | 1.181 | 2.677 | 2.205 | 0.63 | 2.11 | 297814830 |

| 7/8″ | – | 9 | 11,023 | 5,512 | 2.756 | 1.378 | 1.949 | 0.748 | 1.181 | 2.677 | 2.205 | 0.63 | 2.45 | 297815630 |

| 1″ | – | 8 | 13,889 | 6,945 | 3.363 | 1.575 | 2.374 | 0.866 | 1.181 | 3.202 | 2.727 | 0.71 | 3.11 | 297816430 |

| 1-1/4″ | – | 7 | 26,015 | 17,637 | 4.541 | 1.969 | 3.159 | 1.063 | 1.969 | 4.344 | 3.554 | 0.87 | 8.00 | 297818050 |

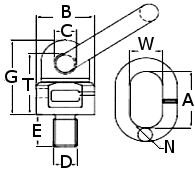

Metric Size - Red Base

| Tap Size | Dimensions (mm) | WLL at Lift Angle (tons) | Weight (lbs/pc) | Vanguard Code | ||||

| A | E | W | Ø | 0 Deg. | 90 Deg. | |||

| M8 | 55 | 13 | 30 | 13 | 0.60 | 0.30 | 0.92 | 2978 20813 |

| M8 | 55 | 18 | 30 | 13 | 0.60 | 0.30 | 0.95 | 2978 20818 |

| M10 | 55 | 18 | 30 | 13 | 0.90 | 0.45 | 0.96 | 2978 21018 |

| M10 | 55 | 25 | 30 | 13 | 0.90 | 0.45 | 1.11 | 2978 21025 |

| M12 | 55 | 20 | 30 | 13 | 1.00 | 0.50 | 1.11 | 2978 21220 |

| M12 | 55 | 27 | 30 | 13 | 1.00 | 0.50 | 1.11 | 2978 21227 |

| M16 | 55 | 24 | 30 | 13 | 2.00 | 1.12 | 1.11 | 2978 21624 |

| M16 | 55 | 30 | 30 | 13 | 2.00 | 1.12 | 1.12 | 2978 21630 |

| M16 | 55 | 35 | 30 | 13 | 2.00 | 1.12 | 1.15 | 2978 21635 |

| M20 | 85 | 30 | 40 | 18 | 4.00 | 2.00 | 2.14 | 2978 22030 |

| M20 | 85 | 43 | 40 | 18 | 4.00 | 2.00 | 2.20 | 2978 22043 |

| M24 | 85 | 30 | 40 | 18 | 6.30 | 3.15 | 3.22 | 2978 22430 |

| M24 | 85 | 38 | 40 | 18 | 6.30 | 3.15 | 3.27 | 2978 22438 |

| M30 | 115 | 35 | 50 | 25 | 10.60 | 5.30 | 4.81 | 2978 23035 |

| M30 | 115 | 50 | 50 | 25 | 11.80 | 8.00 | 8.30 | 2978 23050 |

| M36 | 115 | 54 | 50 | 25 | 11.80 | 8.00 | 8.65 | 2978 23654 |

Grade 80 Video

- Fast, easy assembly without the need for special tools or skills.

- Designed for attaching hooks, master links and other end fittings to Grade 80 alloy chain.

- Approved for overhead lifting, when all components are grade 80

- Easily attaches to Grade 80 chain with pin and cotter.

- Approved for overhead lifting, when all components are grade 80

VGD Grade 80 Slip hook with latch

- Easily attaches to Grade 80 chain with pin and cotter.

- Approved for overhead lifting, when all components are grade 80

Self Locking Style Hooks

VGD Grade 80 Self Locking SC Hook

- Easily attaches to Grade 80 chain with pin and cotter.

- The latch on this hook automatically closes when pulling force is applied.

- Approved for overhead lifting, when all components are grade 80.

VGD Grade 80 Self locking swivel hook

- The latch on this hook automatically closes when pulling force is applied.

- Approved for overhead lifting, when all components are grade 80.

pages

- Marking GP Shackles

- ANTOX

- Cable & Wire Rope

- Firefighting Promo Page 2024

- What is VGD?

- What is VQ

- Paperless

- University of Vanguard

- Abrasives/Brushes

- Firefighting Promotion Thank you

- Firefighting Promotion Order Form

- Calculators

- Resources and Useful Links

- STEEL WEIGHT CALCULATOR

- Specialty Steel

- Hardware

- Contact

- Industrial Knives

- Welding

- Home

© 2024 Vanguard Steel Ltd. All Right Reserved