- 1-866-294-3191

- Open Monday to Friday 8am to 5pm

- Emergency Callout Available

Grade 100 Alloy Lifting

Certified quality: the philosophy of facts over mere intentions

The H92 mark is stamped on each individual product in the CARTEC line

Quality Management System, this has been up and running since 1995 in compliance with EN ISO 9001 standards and then in 2014, it gained certification issued by DNV.

The Environmental Management System is also certified by DNV, in accordance with the EN ISO 14001:2015 standard.

DGUV ACCREDITATION FOR THE ‘H92’ MARK

As of now, Cartec’s brand remains the sole Italian company within its industry to have earned accreditation with the H92 mark from the German organization DGUV.

However, one of Cartec’s major successes is the accreditation from the German safety institution DGUV – PRÜFZERT PZNM – EISEN METALL I, as it is the only Italian company to date whose hot forging process used for the manufacture of lifting accessories has obtained this recognition. This internationally recognized accreditation certifies the reliability of its processes and the products offered to the market. Obtained in 1997 in relation to the production of grade 80 and grade 100 accessories in compliance with the EN818 and EN1677 standards, this accreditation is represented by the prestigious H92 mark.

Another reason to buy Vanguard

Colour Grade change 440ºF - 530ºF - 570ºF - 610ºF - 660ºF - 750ºF

Since early 2000, all CARTEC items grade 80 and grade 100 are supplied with photochromatic paint. This paint has the characteristic of being an excellent overheating indicator because it can change its colour while temperature rises. Over 390ºF, the product colour changes from red/orange to brown and it becomes black at 750ºF.

Reasons for capacity reductions

| Environment temperature | Reduction |

|---|---|

| Below -40°C | Not Allowed |

| From -40°C to 200°C | None |

| From 200°C to 300°C | - 10% |

| From 300°C to 380°C | - 25% |

| Above 380°C | Not allowed |

ASSEMBLY INSTRUCTIONS

(Dir. 2006/42/EC s.m.i Ali. VI )

1) The device is intended to be incorporated on a lifting sling and include a user and maintenance manual with the following: how to use, testing before uses, limits and prohibitions.

2) Check correct assembly with chains/accessories in compliance to the dimensions and capacity.

3) The device for the sling shall be assembled by a competent and qualified person.

4) Before using each time, make sure that the lifting accessory does not have defects due to te wear, corrosion, cracks or visible deformations, the marking is clearly legible, all components are assembled and installed properly.

5) In regards to lifting accessories, the devices for slings have to undergo inspections at regular intervals and recorded in a specific logbook at yearly intervals at least.

For particularly heavy work we suggest the following regular intervals:

• Six monthly: if accessories are used rarely;

• Quarterly: if accessories are used normally;

• Monthly: if accessories are used intensely;

Staff must check that:

-The markings are clearly legible;

-The lifting accessory at the point of contact between the chain hook/connection mesh has not suffered wear higher than 10% compared with the initial measurement

-The hook has not undergone a permanent deformation or change in shape and has not suffered distortion causing an increase in the throat opening by 10% or more.

If only one of the aforementioned checks does not comply with the parameters shown, the sling is to be considered not suitable and safe for lifting; therefore it must be disposed of and no longer used.

6) In case of strong magnetic fields, before each use, carefully check that the lifting accessory components are assembled correctly and that they have net suffered deformations that would affect their operation and safety; otherwise, the accessory must be replaced.

7) After assembly, make sure that:

• the load pin inserted in the hook clevis is locked with the spring pìn.

• the load pin inserted in the coupling links are secured properly by the split ring retainer pin.

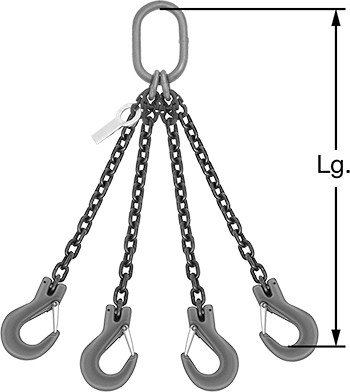

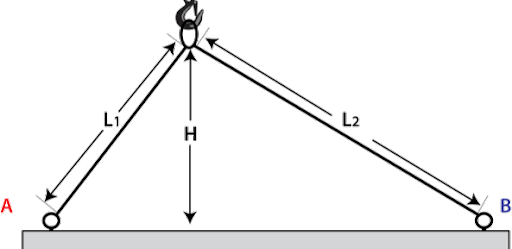

8) The operating load WLL varies depending on the lifting angle and the type of sling on which the device is assembled on.

10) 4:1 Design factor

11) The accessory can be used safely until I a maximum of 20.000 cycles at or below WLL

12) If parts or the accessory are replaced only spare parts or the original CARTEC kit provided by the manufacturer should be used

13) Store the accessory in a suitable space ( e.g. Dry, not corrosive etc.)

14) Net suitable te be used in acid environments, or highly corrosive with chemical substances, in explosive environments, with a temperature higher than 380°C or lower than – 40°C

15) Do not exceed operating loads referred te on the reference chart

16) Do not use for operations which defer from the ones that are foreseen

17) Not suitable to lift people

18) If the instructions are not adhered to, serious damage can be caused to things and injuries or death to people

19) If changes, repairs and/or treatments are made to the product, the terms of the guarantee are no longer applicable and the manufacturer declines all liability

20) lt is forbidden the use or lifting accessories without a latch to help prevent sudden and involuntary loss and fall of the load

21) Sale use or the foundry hook or series CYX, CYFX and any other accessories without a safety device. lt is mandatory for those performing lifting operations using

accessories without a latch to take all necessary measures to ensure the safety of people (i.e. compartmentalization and safe arrangement of the manoeuvring area, limitation of lift heights, etc.).

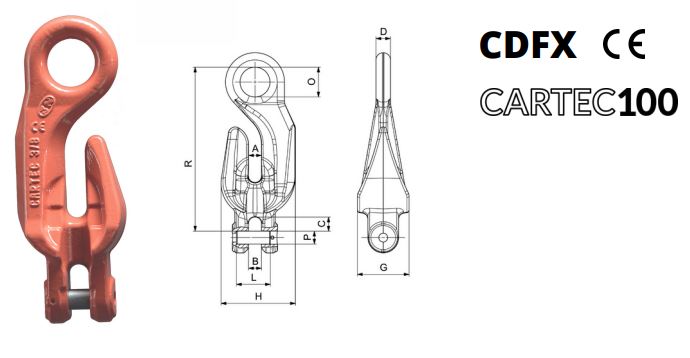

Clevis shortening hook

Now In Stock

Videos

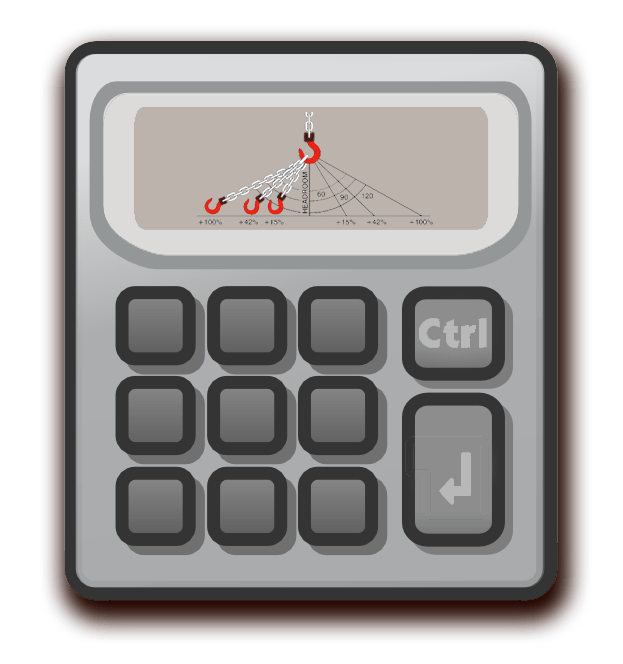

GRADE 100 CHAIN SLING CALCULATOR

*See bottom for detailed instructions on how to use the Chain Sling Calculator

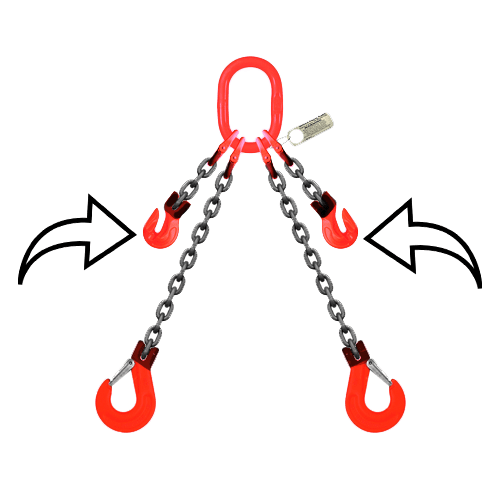

Select the style of chain sling you require

Calculator not mobile friendly

Important instructions – Please read carefully

Here are a few things you will need to understand before using this calculator.

- Select the Grade and Size from the bottom tabs

- Enter the length of the leg of the chain sling and press Enter

(Note: You only have access to the “length field”. Yellow box with the number 1) - You will need to call in for Prices

- Select the type of sling you require

- Directly beside the picture of the type of sling, you will see how many units you will require

In the light green cells of each type of sling will be the name of the sling (example: SOS | Call 4 Price)

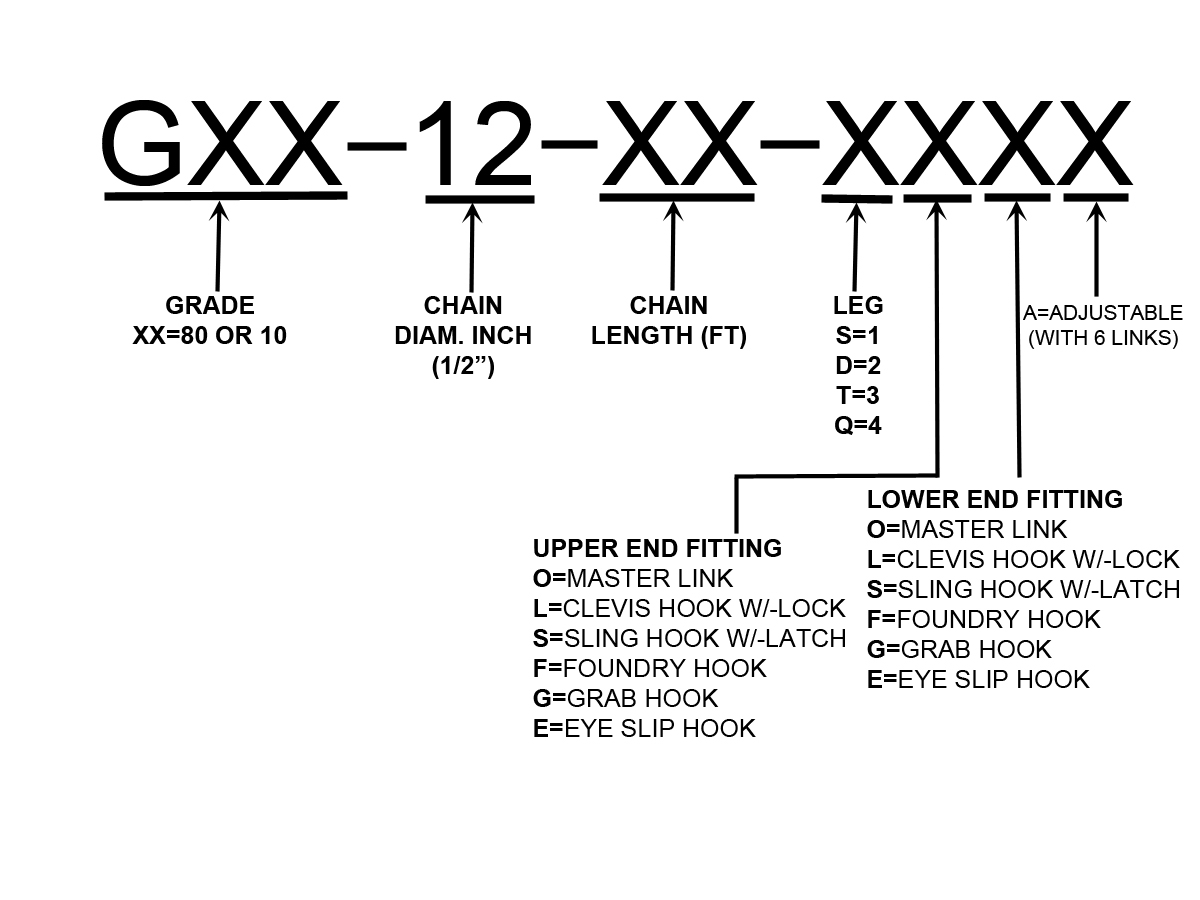

Understanding the description and how to order

1.Select the grade of chain.

2.Select the size of chain based of the load you need to lift.

3.Select the length of the legs you require.

4.Select the number of legs you need.

5.Select upper side of sling.

i.e. “S” single and then “O” Master link or “G” Grab etc…

6.Select lower end fitting.

7.Select if you want to be able to adjust by adding an “A” (sometimes added at the beginning as above diagram)

Standard Type Slings

Standard Type of Hooks

Adjustable Style

pages

- Marking GP Shackles

- ANTOX

- Cable & Wire Rope

- Firefighting Promo Page 2024

- What is VGD?

- What is VQ

- Paperless

- University of Vanguard

- Abrasives/Brushes

- Firefighting Promotion Thank you

- Firefighting Promotion Order Form

- Calculators

- Resources and Useful Links

- STEEL WEIGHT CALCULATOR

- Specialty Steel

- Hardware

- Contact

- Industrial Knives

- Welding

- Home

© 2024 Vanguard Steel Ltd. All Right Reserved