Trulock G10 SL Clevis Slip Hook

The Trulock SL Clevis Slip Hook is engineered for secure and adaptable lifting, providing a robust solution for a wide range of rigging applications. Designed with a convenient clevis connection, this hook allows for direct attachment to your chain sling assemblies, eliminating the need for additional coupling links and streamlining your setup. Its design prioritizes both strength and versatility, making it an indispensable component for professionals who demand reliable performance in diverse lifting scenarios, from pulling and securing to general material handling.

Key Features of the Trulock SL Clevis Slip Hook:

Forged from specialty alloy steel and meticulously heat-treated for superior strength and durability.

Optimized to be seamlessly matched with Grade 100 chains, ensuring peak performance and compatibility.

Delivers a performance increase of 25% when compared to standard Grade 80 products, offering enhanced lifting capacity.

Each individual hook is rigorously tested at 2.5 times its working load limit, with certification available.

Samples undergo comprehensive fatigue testing, enduring 20,000 cycles at 1.5 times the Working Load Limit, guaranteeing long-term reliability.

Strict sampling and breakage testing are conducted for every batch of products, ensuring consistent quality and safety.

100% magnetic particle flaw detection is performed on each hook to identify any subsurface imperfections.

100% of the pins are individually tested to ensure uniform hardness, contributing to overall product integrity.

Features a durable powder-coated surface treatment for enhanced corrosion resistance and extended lifespan.

Distinctive colour code: Peach with a black tip for easy identification and brand recognition.

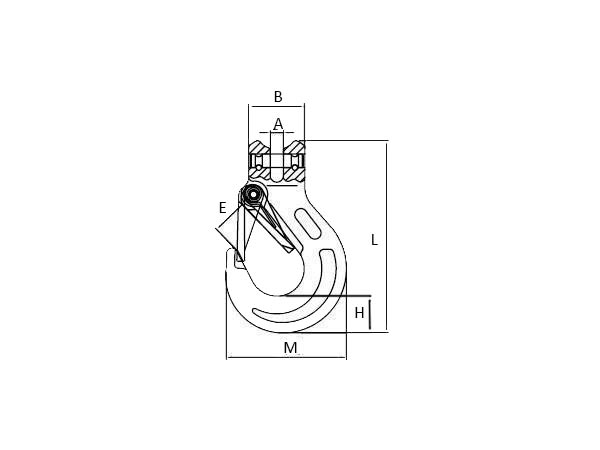

| Model | Part Number | WLL (t) | Breaking Load (t) | A±.05 | B±1 | E±1.5 | H± | M±2 | L±2.5 | Weight (KG) |

|---|---|---|---|---|---|---|---|---|---|---|

| 10-VQSH1004-08 | 3951 5016 | 2.5 | 10 | 9.5 | 37 | 25 | 27.5 | 88 | 134 | .7 |

| 10-VQSH1004-10 | 3951 5024 | 4 | 16 | 12 | 48 | 28 | 33.5 | 105.5 | 161.5 | 1.3 |

| 10-VQSH1004-13 | 3951 5032 | 6.7 | 26.8 | 15 | 59 | 38 | 42 | 134 | 203 | 2.3 |

| 10-VQSH1004-16 | 3951 5040 | 10 | 48 | 17.5 | 70 | 44 | 50 | 160.5 | 248 | 3.6 |

| 10-VQSH1004-20 | 3951 5048 | 16 | 64 | 25 | 85. | 52 | 56 | 190.5 | 297 | 7.3 |

Other Products

Inspection Considerations for G80 and G100 Alloy Sling Hook

Inspecting a Grade 100 sling hook involves a series of steps to ensure the hook is safe for lifting and meets industry standards. Here’s a detailed guide on how to inspect a Grade 100 sling hook:

Visual Inspection

Check for Identification: Ensure that the sling hook has clear identification markings, including the grade, manufacturer’s mark, and traceability code. This helps verify that the hook is a genuine Grade 100 product.

Inspect for Deformation: Look for any signs of deformation such as bends, twists, or elongation. Deformed hooks indicate that the hook has been overloaded and should be removed from service.

Surface Examination: Check the hook for any cracks, gouges, nicks, and corrosion. Surface defects can weaken the hook and compromise its integrity. Pay special attention to the areas around the throat and hook body.

Examine the Hook Tip: Ensure that the tip of the hook is not bent or damaged. The hook tip should be properly aligned and free of sharp edges.

Check the Hook Throat Opening: Measure the throat opening of the hook to ensure it has not widened beyond the manufacturer’s specifications. An increased throat opening is a sign of overload and can be dangerous.

Functional Inspection

Movement of the Hook Latch: Verify that the hook latch (if equipped) moves freely and returns to its closed position automatically. The latch should securely cover the hook opening and should not be bent or damaged.

Swivel Action (if applicable): If the sling hook is a swivel type, ensure that the swivel mechanism operates smoothly without excessive play or binding.

Measurement and Comparison

Dimensional Check: Use precise measuring tools to check the dimensions of the hook against the manufacturer’s specifications. Focus on critical areas such as the throat opening, hook body, and latch.

Wear and Corrosion: Measure any wear on the hook, particularly in areas where it contacts other lifting components. Corrosion should also be checked as it can weaken the hook over time.

Load Test (if required)

- Proof Load Test: Some standards and manufacturers may require a proof load test to ensure the hook can handle its rated capacity. This should be done according to the manufacturer’s guidelines and industry standards.

Record Keeping

Documentation: Record all findings in an inspection log. Include the date of inspection, condition of the hook, any defects found, and actions taken (such as removal from service).

Traceability: Maintain traceability records that link the sling hook to its inspection history. This is important for compliance with safety standards and for future reference.

Compliance Check

OSHA and Local Regulations: Ensure the inspection complies with OSHA regulations and any local safety standards. This may include additional requirements for documentation, frequency of inspections, and criteria for removing hooks from service.

Manufacturer Guidelines: Follow the manufacturer’s inspection and maintenance guidelines. These often include specific criteria for wear and deformation unique to their products.

Guidelines and References

- OSHA Standards: Check OSHA’s regulations for rigging hardware and sling inspection.

- WorkSafeBC: Refer to WorkSafeBC guidelines for regional compliance.

- Manufacturer’s Manual: Always refer to the specific manufacturer’s manual for detailed inspection procedures and criteria.

By following these steps, you can ensure that Grade 100 sling hooks are in safe working condition, preventing accidents and maintaining compliance with safety regulations. Regular inspections and proper documentation are essential to the longevity and reliability of lifting equipment.

Always check your local laws and governing bodies in your region to ensure compliance with all relevant regulations and standards for chain sling inspections.

Accuracy Disclaimer: While we strive to provide accurate and up-to-date inspection information, please be aware that regulations, standards, and guidelines may change. It is important to verify the information provided by your local governing bodies or relevant authorities to ensure compliance with current regulations and requirements.