G10 VQ Swivel Self-Locking Hook w/ Ball Bearings

- The ball bearing inside a swivel hook isn’t just for rotation — it also absorbs side-loading forces, keeping the hook body and latch aligned under tension for longer service life.

Grade 100 VQ Self-Locking Hook with Bearing, a top-tier lifting solution forged from high-strength alloy steel and engineered for superior performance and safety. Ideal for heavy-duty applications, this hook is compatible with G100 chains.

- Forged specialty alloy steel, and then heat treated;

- Can be matched with G100 chains;

- Performance is increased by 25% compared with G80 products;

- Each Piece is tested at 2.5 times the working load limit;

- Fatigue testing is carried out on samples to 20,000 times;

- Strict sampling and breakage testing is conducted for each batch of products;

- 100% magnetic powder flaw detection is performed;

- 100% of the pins are tested to ensure they have the same hardness;

- Surface treatment: Powder Coated;

- Color code: Peach with black tip;

- Equipped with a self-locking mechanism and a bearing for smooth operation.

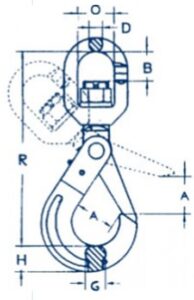

| SL Swivel Grade 100 | Dimensions (Inches) | WLL | Lbs | Product | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Code | Chain Size | R | A | B | O | D | G | H | Lbs | Pc | Code | |

| VSC-7/8 | 9/32-5/16" | 7.17 | 1.34 | 1.06 | 1.42 | 0.51 | 0.73 | 1.02 | 5,700 | 2.42 | 39705016 | |

| VSC-10 | 3/8" | 8.54 | 1.77 | 1.38 | 1.65 | 0.63 | 0.98 | 1.18 | 8,800 | 4.40 | 39705024 | |

| VSC-13 | 1/2" | 10.67 | 2.13 | 1.69 | 1.97 | 0.83 | 1.38 | 1.57 | 15,000 | 8.8 | 39705032 | |

| VSC-16 | 5/8" | 12.60 | 2.44 | 2.28 | 2.44 | 0.94 | 1.50 | 1.97 | 22,600 | 14.96 | 39705040 | |

| 4:1 | ||||||||||||

Other Products

Grade 100 VQ Swivel Self-Locking Hook with Ball Bearings Inspection Guide

Inspecting a Grade 100 VQ swivel self-locking hook with ball bearings is essential to ensure compliance with industry standards like WorkSafeBC and OSHA, and to guarantee safety during use. Below is a comprehensive guide to help you perform a thorough inspection of this hook:

Visual Inspection

Identification Marks: Ensure that the hook has clear identification markings, including the grade (Grade 100), manufacturer’s mark, and traceability code. These are critical for verifying that the hook meets required specifications.

Deformation Check: Look for any signs of deformation such as bends, twists, or elongation. Deformed hooks indicate overloading or improper use, and any hook showing deformation should be immediately removed from service.

Wear Inspection: Inspect for wear in the hook body, particularly around the ball bearings and latch mechanism. Excessive wear can compromise the integrity of the hook. Measure worn areas and compare them with the manufacturer’s specifications to determine if the hook is still fit for use.

Surface Defects: Look for surface defects such as cracks, gouges, nicks, and signs of corrosion. These can indicate deeper issues and may lead to equipment failure under load.

Heat Exposure: Check for signs of heat damage, like discoloration. Heat can weaken the treated steel, and Grade 100 hooks are especially susceptible to changes in mechanical properties if exposed to high temperatures.

Functional Inspection

Ball Bearing and Swivel Movement: The ball bearings should allow for smooth swivel movement without any binding or resistance. Proper movement is critical for reducing stress on the hook during load rotation.

Latch Operation: Ensure the self-locking latch mechanism is functioning properly and securely locks when under load. Any malfunction in the locking mechanism could lead to accidental load release.

Component Fit and Alignment: Verify that the hook and its associated components, such as the latch and ball bearings, are properly aligned and function smoothly together. Misalignment or difficulty in movement may indicate wear or damage.

Measurement and Dimensional Check

Dimensional Accuracy: Use calipers or similar tools to measure the hook’s critical dimensions, such as throat opening and hook body thickness. Compare these measurements with the original specifications to confirm the hook hasn’t been overstretched or deformed.

Ball Bearing Inspection: Examine the ball bearings for wear or damage. They should rotate smoothly under load without any grinding or seizing. Damaged ball bearings can lead to uneven load distribution and potential failure.

Documentation and Traceability

Record Inspection Results: Document the inspection date, hook condition, any defects found, and actions taken. This log will help track the hook’s lifecycle and maintain compliance with safety regulations.

Maintain Traceability: Ensure that the hook’s traceability code is recorded alongside its inspection history. This practice is vital for compliance with industry standards and for ensuring that no damaged or worn hooks are kept in service.

Compliance Check

Regulatory Compliance: Confirm that the inspection follows OSHA, WorkSafeBC, or local safety standards, especially those related to lifting and rigging equipment. These regulations often outline mandatory inspection intervals and specific criteria for removing hooks from service.

Manufacturer’s Guidelines: Adhere to the manufacturer’s recommendations for inspecting the hook, particularly for wear limits and proper use of the swivel and self-locking mechanisms. Following the manufacturer’s guidance ensures the equipment’s long-term safety and performance.

Summary

By regularly performing these steps, you can ensure that your Grade 100 VQ swivel self-locking hook with ball bearings is in compliance with safety standards, remains in good working condition, and helps prevent accidents in the workplace.

For further information, consult the following resources:

- WorkSafeBC regulations

- OSHA standards

- Manufacturer’s product manual

This ensures a robust safety management process and extends the lifespan of your lifting equipment.

Always check your local laws and governing bodies in your region to ensure compliance with all relevant regulations and standards for chain sling inspections.

Accuracy Disclaimer: While we strive to provide accurate and up-to-date inspection information, please be aware that regulations, standards, and guidelines may change. It is important to verify the information provided by your local governing bodies or relevant authorities to ensure compliance with current regulations and requirements.