Grade 100 VQ Master Link

Grade 100 VQ Master Link, a top-tier lifting solution forged from high-strength alloy steel and engineered for superior performance and safety. Ideal for heavy-duty applications, this hook is compatible with G100 chains

- Forged specialty alloy steel, and then heat treated;

- Can be matched with G100 chains;

- Performance is increased by 25% compared with G80 products;

- Each Piece is tested at 2.5 times the working load limit;

- Fatigue testing is carried out on samples to 20,000 times;

- Strict sampling and breakage testing is conducted for each batch of products;

- 100% magnetic powder flaw detection is performed;

- 100% of the pins are tested to ensure they have the same hardness;

- Surface treatment: Powder Coated;

- Colour code: Peach;

- All sizes are forged

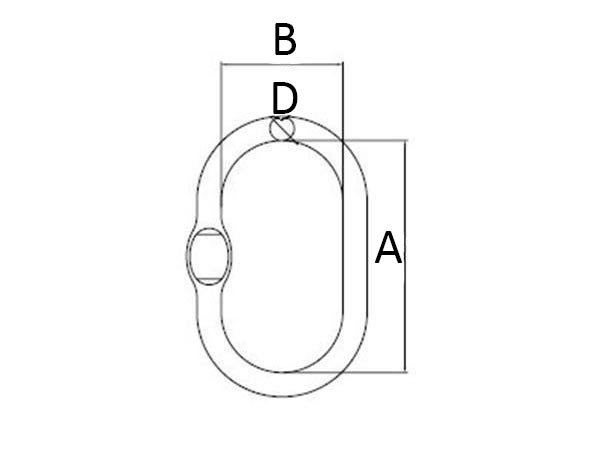

| Model | Part Number | WLL lbs | D | L | P | Weight lbs |

|---|---|---|---|---|---|---|

| VML132 | 3953 00323 | 4,700 | 1/2" | 2.36 | 4.33 | .8 |

| VML140 | 3953 00403 | 8,600 | 5/8" | 2.36 | 4.33 | 1.55 |

| VML148 | 3953 00483 | 12,900 | 3/4" | 2.95 | 5.31 | 2.70 |

| VLM156 | 3953 00563 | 17,600 | 7/8" | 3.62 | 6.5 | 3.31 |

| VML1100 | 3953 01003 | 30,000 | 1" | 3.94 | 7.09 | 5.30 |

| VML1116 | 3953 01163 | 38,200 | 1-1/4" | 4.33 | 7.87 | 9.75 |

| VML1132 | 3953 01323 | 50,200 | 1-1/2" | 5.51 | 10.24 | 18.00 |

Other Products

Inspection Considerations for G80 and G100 Alloy Master Link

Inspecting a Grade 100 master link, such as the G100 VQ MLX Master Link, typically involves a visual and tactile examination for signs of wear, damage, or deformation. Here are the general steps:

Visual Inspection:

- Look for any signs of wear, such as elongation of the link or excessive wear on the bearing surfaces.

- Check for cracks, nicks, or gouges on the surface of the link.

- Inspect the welds (if applicable) for any signs of cracking or incomplete penetration.

- Look for any signs of heat damage, such as discoloration or distortion.

Measurement:

- Measure the dimensions of the master link to ensure it meets the manufacturer’s specifications.

- Check the diameter of the pin and the width of the link to ensure they are within tolerance.

Load Pin Inspection:

- Ensure the load pin is free from cracks, nicks, or gouges.

- Check the threads of the pin for wear or damage.

Functional Check:

- Check the functionality of the link, ensuring it opens and closes smoothly.

- Verify that the locking mechanism, if present, engages properly.

Documentation:

- Keep a record of the inspection, including any measurements taken and observations made.

- Note the date of inspection and the person performing the inspection.

It’s important to refer to the manufacturer’s guidelines and specifications for the specific inspection requirements of the Grade 100 master link you are using, as these may vary.

By performing these steps, you ensure that Grade 100 master links are safe for use and comply with all relevant standards and regulations. Regular inspections help prevent accidents and extend the life of your lifting equipment.

For more detailed guidelines, you can refer to resources such as:

- OSHA standards

- WorkSafeBC (WorkSafeBC) (WorkSafeBC)

- Manufacturer-specific guidelines from the product manual.

Always check your local laws and governing bodies in your region to ensure compliance with all relevant regulations and standards for chain sling inspections.

Accuracy Disclaimer: While we strive to provide accurate and up-to-date inspection information, please be aware that regulations, standards, and guidelines may change. It is important to verify the information provided by your local governing bodies or relevant authorities to ensure compliance with current regulations and requirements.