- 1-866-294-3191

- Open Monday to Friday 8am to 5pm

- Emergency Callout Available

SPECIALTY STEEL

Menu

4140 – 4340 – 8620 – 3312 – EN30B – 4145

C1018 – C1020 – C1040/45 – 12L14

CPO – IHCP Induction

65-45-12

Basic Price Breakdown of Steel

The basic price considers labour costs, machinery costs, market trends etc. Mills often negotiate the basic price with customers independently from the alloy surcharge prices.

The component “extras” includes charges for non-standard dimensions, different thicknesses, services, packing and other non-standard costs.

The alloy surcharge is based on the price levels of the following elements present in common steel: nickel, chromium, scrap, vanadium, manganese and iron (the latter two having a smaller impact on the price). There cannot be any negative alloy surcharges.

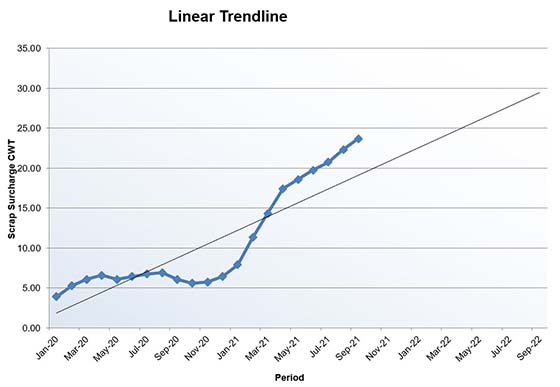

Scrap Surcharge

WITH A PHILOSOPHY “LARGE ENOUGH TO MATTER, SMALL ENOUGH TO CARE” WE TRY HARDER.

We understand that service and speed is or maybe more important than price in today’s competitive economy. With pressure from around the globe and commodity prices in constant change, it is increasingly difficult to find large quantities of local stock.

over 80,000 square feet covered

6 automatic saws; with capacity to 32” diameter

Full traceable on all specialty steel

Either cut to size or random length.

At Vanguard Steel, we are doing our best to support our local industrial manufacturers by keeping stock locally.

If there are any items you have trouble sourcing, let our sales team know and we will check our network and stock them here.

Alloy bar, Mild steel, Cold finished shafting to precision. We stock a wide variety of bar. 660 bronze and Aluminum Bronze are new additions to our line. Give us a call and check out our line card for more details.

An alloy bar is a type of metal bar made from a combination of two or more metallic elements. Alloys are formed by mixing and melting different metals together to create a new material with specific properties, such as increased strength, corrosion resistance, or conductivity. The resulting alloy can be cast into different shapes, including bars, rods, and sheets, which can be used in various applications in industries such as construction, automotive, aerospace, and manufacturing. Common alloy bar materials include stainless steel, brass, bronze, and aluminum.

Alloy Bar and Colour Code

Click colour grade for detailed information

4340 steel is a type of alloy steel that contains a high percentage of chromium, molybdenum, and nickel. It is known for its high strength, toughness, and durability, and is commonly used in the manufacturing of high-strength machine parts, such as aircraft landing gear, crankshafts, and transmission gears.

The “43” in its name refers to the approximate amount of carbon content in the steel, and the “40” refers to the percentage of chromium and molybdenum in the alloy. This combination of elements gives 4340 steel its high tensile strength, as well as good fatigue resistance and wear resistance.

4340 steel can be heat-treated to increase its strength and hardness, and can also be machined and welded. It is often used in demanding applications where high strength and durability are required, such as in the aerospace, defense, and automotive industries.

4140 steel bar is a type of alloy steel that is commonly used in various industrial applications. It is a low alloy steel that contains chromium, molybdenum, and manganese as primary alloying elements. The combination of these elements provides the steel with high strength, toughness, and wear resistance.

4140 steel bars come in various shapes and sizes, including round bars, square bars, and hexagonal bars. They are often used in the manufacturing of machinery parts, such as gears, shafts, and axles, as well as in the construction of structural components, such as bridges and buildings.

This steel can be heat-treated to improve its mechanical properties, making it suitable for a wide range of applications that require high strength and durability. 4140 steel bar is often referred to as “chromoly” due to its chromium and molybdenum content.

4140 precision ground refers to a type of 4140 steel bar that has been machined to a precise, smooth surface finish and tight dimensional tolerances. The process of precision grinding involves using abrasive wheels to remove small amounts of material from the surface of the steel bar, resulting in a very smooth and even surface.

Precision ground 4140 steel bars are commonly used in applications that require tight tolerances and precise dimensions, such as in the manufacturing of precision machinery components and tools. The precision grinding process ensures that the steel bar has a uniform size and shape, as well as a smooth surface finish, which can help to reduce friction and wear in machinery and equipment.

Overall, precision ground 4140 steel bars offer excellent strength, durability, and wear resistance, making them a popular choice for a wide range of industrial applications.

4145H Modified steel is a type of low alloy steel that contains chromium, molybdenum, and nickel as primary alloying elements. It is a modified version of 4140 steel and is often used in oil and gas drilling applications due to its high strength, toughness, and resistance to fatigue and wear.

The “H” in 4145H Modified steel stands for “heat-treated,” which means that the steel has been subjected to a heat treatment process to improve its mechanical properties. The modified version of 4140 steel provides better hardenability and strength than the original 4140 steel.

4145H Modified steel is often used in the manufacturing of drill collars, which are used to provide weight to the drill bit and help to keep it on course during drilling. It is also used in other oil and gas drilling components, such as drill rods and stabilizers.

Overall, 4145H Modified steel is a high-strength, durable, and wear-resistant material that is well-suited for use in demanding oil and gas drilling applications.

AISI 8620 Steel: Versatility and Strength for Demanding Applications

AISI 8620 steel is a versatile, low-carbon, nickel-chromium-molybdenum alloy steel renowned for its exceptional balance of strength, toughness, and machinability. Its carefully controlled chemical composition, featuring nickel, chromium, and molybdenum as key alloying elements, is what gives it these desirable properties. The low carbon content allows for effective carburizing, a process that dramatically increases surface hardness while maintaining a ductile core. This combination of properties makes 8620 steel a go-to material for demanding industrial applications.

The excellent machinability of 8620 steel allows for efficient and precise fabrication, reducing manufacturing costs and time. Its weldability, while requiring proper pre- and post-weld heat treatment, makes it adaptable to various fabrication processes. This combination of workability and strength makes 8620 steel ideal for a wide array of critical components, including:

- Gears (spur, helical, bevel) requiring high surface hardness and core strength.

- Shafts and axles subjected to torsional and bending stresses.

- Heavy-duty pins and fasteners.

- Automotive components such as camshafts, crankshafts, and transmission parts, where wear resistance and load-bearing capacity are paramount.

- Aerospace structural components.

- Bearing races.

- Industrial tooling.

8620 steel’s response to heat treatment, particularly carburizing, is a key factor in its versatility. Through carburizing, a hard, wear-resistant case is created, while the core retains its inherent toughness. Other heat treatments, such as quenching and tempering, can be employed to tailor the steel’s mechanical properties to specific application requirements. This allows for precise control over hardness, tensile strength, yield strength, and impact resistance, making 8620 steel suitable for demanding applications where high-strength and wear-resistant materials are essential.

In conclusion, 8620 steel stands as a testament to the power of alloy design, offering a remarkable combination of strength, toughness, machinability, and wear resistance. Its ability to be effectively carburized and heat-treated allows for customization to meet the stringent demands of diverse industrial applications. When reliability and performance are critical, 8620 steel provides a robust and cost-effective solution.

3312 alloy steel is a low-alloy steel that is commonly used in industrial applications. It contains a combination of elements including chromium, molybdenum, and nickel that provide the steel with high strength and toughness.

3312 alloy steel can be heat-treated to improve its mechanical properties, such as hardness and strength. This makes it suitable for use in a wide range of applications, including the manufacturing of industrial machinery components, such as gears, shafts, and axles, as well as structural components, such as bridges and buildings.

Due to its high strength and wear resistance, 3312 alloy steel is often used in applications that require materials to withstand heavy loads and harsh environments. It is also known for its good machinability and weldability, which make it easy to work with during the manufacturing process.

Overall, 3312 alloy steel is a versatile and durable material that offers a good balance of strength, toughness, and machinability, making it a popular choice for a wide range of industrial applications.

EN30B steel is a low alloy steel that is commonly used in industrial applications. It is also known as 835M30 or 30NiCrMo16, and it contains a combination of elements, including nickel, chromium, and molybdenum, that provide the steel with high strength, toughness, and wear resistance.

EN30B steel is often used in the manufacturing of gears, shafts, and other components that require high strength and durability. It can also be used in the construction of structural components, such as bridges and buildings.

The steel can be heat-treated to further improve its mechanical properties, such as increasing its hardness and strength. This makes it suitable for use in applications that require high-strength and wear-resistant materials.

Overall, EN30B steel is a versatile and durable material that offers a good balance of strength, toughness, and machinability, making it a popular choice for a wide range of industrial applications.

Carbon Steel Bar and Colour Code

Click colour grade for detailed information

1018 steel, also known as low carbon steel or mild steel, is a commonly used type of carbon steel. It gets its name from its composition, which primarily consists of iron and a small percentage of carbon, typically around 0.18%. This low carbon content makes 1018 steel relatively soft and easy to work with, making it suitable for a wide range of applications in various industries.

Key characteristics of 1018 steel include good weldability, machinability, and formability. It can be easily cut, shaped, and welded, making it a popular choice for manufacturing processes such as machining, welding, and forming. It’s often used in the production of parts and components for machinery, automotive applications, structural elements, and general metalworking.

While 1018 steel is valued for its ease of fabrication, it is not as strong or hard as some other types of steel, such as high carbon or alloy steels. Therefore, it’s important to choose the right material for the specific requirements of a given application. Additionally, 1018 steel is susceptible to corrosion, so appropriate protective measures, such as coatings or plating, may be necessary in certain environments.

1020 hot rolled steel refers to a specific type of carbon steel alloy that has been subjected to the hot rolling process. Hot rolling is a manufacturing process that involves heating a metal ingot or billet until it reaches a malleable temperature and then passing it through a series of rollers to reduce its thickness and shape it into various forms, such as sheets, plates, or bars.

1020 hot rolled steel is often used to produce various components, including structural parts, gears, axles, and other machine parts. It’s known for its versatility, ease of fabrication, and affordability, which contribute to its popularity in many manufacturing processes. Additionally, like other low-carbon steels, 1020 hot rolled steel is not as strong or hard as high-carbon or alloy steels, so it’s important to select the appropriate material for the specific requirements of a given application.

In the case of 1020 hot rolled steel, the “1020” designation typically refers to the chemical composition of the steel. It contains approximately 0.20% carbon, which is relatively low, making it a low-carbon steel. This low carbon content gives 1020 steel good weldability, formability, and machinability, making it suitable for a wide range of applications in industries such as manufacturing, construction, and automotive.

1040 and 1045 are both medium-carbon steel grades commonly used in various industrial applications. They have slightly different carbon content and properties, which make them suitable for specific purposes.

1040 Steel: This grade of steel contains approximately 0.40% carbon, which places it in the medium-carbon steel category. It offers a good balance between strength and ductility, making it suitable for a wide range of applications. 1040 steel is often used in machinery parts, shafts, gears, and general engineering components. It can be heat-treated to improve its hardness and strength.

1045 Steel: 1045 steel contains about 0.45% carbon, slightly higher than 1040 steel. This additional carbon content increases its hardness and strength, making it a stronger material. 1045 steel is commonly used for parts that require higher strength and wear resistance, such as gears, axles, bolts, and hydraulic shafts. It’s also suitable for various machining processes and can be heat-treated to achieve desired mechanical properties.

Both 1040 and 1045 steels are known for their machinability and weldability, making them versatile choices for many applications. However, the choice between the two depends on the specific requirements of a given project. If higher strength and wear resistance are needed, 1045 steel may be preferred, while 1040 steel may be suitable for applications where a balance of strength and ductility is required.

12L14 steel, also known as “Ledloy,” is a free-cutting, resulfurized, and rephosphorized carbon steel. It falls into the category of low-carbon steels and is alloyed with small amounts of sulfur (S) and phosphorus (P). These alloying elements improve its machinability, making it one of the easiest steels to machine, cut, and turn.

Key characteristics of 12L14 steel include:

Machinability: 12L14 steel is renowned for its exceptional machinability. The sulfur and phosphorus additives create small, brittle inclusions in the steel, which facilitate chip breaking during machining. This results in improved tool life, reduced machining time, and smoother finishes.

Weldability: While 12L14 steel is primarily designed for machining, it can be welded using standard welding techniques. However, it’s essential to be cautious, as the sulfur content can lead to weld cracking and reduced weld quality. Precautions such as proper preheating and post-weld heat treatment may be necessary.

Cold Forming: 12L14 steel is also suitable for cold forming operations, such as bending and cold heading. Its enhanced machinability extends to these processes, making it a preferred choice for parts that require complex shapes.

Common applications of 12L14 steel include the production of bolts, screws, nuts, bushings, couplings, and other components in the automotive, manufacturing, and machining industries. Its ease of machining and cost-effectiveness make it a popular choice for parts where tight tolerances and excellent surface finish are required.

Chrome Plated Precision Shafting

Click colour grade for detailed information

C1045 chrome-plated steel refers to a specific type of steel that has been subjected to both a chrome-plating process and is primarily made from C1045 steel, which is a medium-carbon steel with approximately 0.45% carbon content.

Here’s a breakdown of the components and characteristics of C1045 chrome-plated steel:

C1045 Steel: The core material of C1045 chrome-plated steel is C1045 steel, which is known for its medium carbon content. This grade of steel provides a good balance of strength, toughness, and wear resistance.

Chrome Plating: The surface of the C1045 steel is plated with a layer of chromium through an electroplating process. The chrome plating serves several purposes:

- Corrosion Resistance: Chromium is highly resistant to corrosion, protecting the underlying steel from environmental factors.

- Wear Resistance: Chrome plating increases the surface hardness of the steel, making it more resistant to wear and abrasion.

- Smooth Finish: Chrome-plated surfaces have a polished appearance, making them suitable for applications where aesthetics matter.

C1045 chrome-plated steel is commonly used in applications that require a combination of strength, wear resistance, and corrosion resistance. It is often employed for components subjected to heavy loads and adverse environmental conditions, such as hydraulic cylinder rods, piston rods, and various industrial and automotive parts.

By combining the core properties of C1045 steel with the protective and functional characteristics of chrome plating, C1045 chrome-plated steel offers a versatile and durable material for various engineering and manufacturing applications.

Induction-hardened chrome-plated steel is a specialized type of steel that has undergone two distinct processes: induction hardening and chrome plating. These processes are applied to enhance the surface properties and durability of the steel, making it suitable for various engineering and industrial applications. Here’s a breakdown of the key components and characteristics:

Base Steel: The core material is typically medium-carbon steel, such as 1045 or 4140, which provides a good balance of strength and toughness. This base steel is known for its mechanical properties and suitability for further surface treatment.

Induction Hardening: Induction hardening is a heat treatment process that selectively heats the surface of the steel using electromagnetic induction. This rapid and localized heating is followed by quenching, which involves cooling the heated area quickly. Induction hardening increases the hardness and wear resistance of the surface layer while maintaining the core’s toughness. This process creates a hardened layer that is resistant to wear and abrasion.

Chrome Plating: After induction hardening, the steel is chrome-plated. Chrome plating involves applying a layer of chromium onto the surface of the steel through an electroplating process. Chromium provides several key benefits, including:

- Corrosion Resistance: Chromium is highly corrosion-resistant, protecting the steel from rust and environmental factors.

- Smooth Surface: Chrome-plated surfaces have a smooth, polished appearance, making them suitable for applications where aesthetics matter.

- Additional Wear Resistance: The combination of induction hardening and chrome plating enhances the overall wear resistance of the steel.

Induction-hardened chrome-plated steel is commonly used for applications requiring high wear resistance and corrosion resistance, such as hydraulic cylinder rods, piston rods, and other industrial components subjected to heavy loads and harsh environments. This combination of processes results in a durable and long-lasting material that can withstand demanding conditions while maintaining a smooth and polished surface finish.

Ductile Iron (VanCast)

Click colour grade for detailed information

Ductile iron 65-45-12 is a specific grade of ductile iron, also known as nodular cast iron or spheroidal graphite iron. It is named after its unique microstructure, which consists of graphite nodules (spheroids) embedded in a matrix of ferrite and pearlite. The numbers “65-45-12” represent the key mechanical and chemical properties of this ductile iron grade:

Tensile Strength (65 ksi): The “65” in the designation indicates the minimum tensile strength of the material in thousands of pounds per square inch (ksi). In this case, the minimum tensile strength is 65 ksi. This property measures the material’s ability to withstand axial loads or stretching forces without breaking.

Yield Strength (45 ksi): The “45” represents the minimum yield strength, also measured in thousands of pounds per square inch (ksi). Yield strength is the point at which the material begins to deform plastically. For ductile iron 65-45-12, the minimum yield strength is 45 ksi.

Elongation (12%): The “12” signifies the minimum elongation at failure, expressed as a percentage. Elongation measures the ability of the material to deform before it breaks. Ductile iron 65-45-12 has a minimum elongation of 12%.

Ductile iron 65-45-12 is valued for its combination of high strength, good ductility, and excellent machinability. It is commonly used in various applications, including automotive components, gears, brackets, and other parts where a balance of strength and ductility is required. This grade of ductile iron is known for its castability and ability to resist deformation under stress, making it a versatile material for engineering and manufacturing purposes.

SERVICES

HIGH-TECH AUTOMATIC SAW CUTTING

• 6 Saws in Vancouver

• Cutting Capacity to 34″ Diameter

• Fully Automatic to accommodate tight tolerances on multiple-piece quantities

• Custom Cutting

CUSTOMER SERVICE

We understand that service and speed are more important in today’s competitive economy than ever before.

• Same-Day-Service available

• Free Delivery for local customers on qualifying orders

QUALITY & TRACEABILITY

We only carry the best quality of steel with Mill Certificates that carry additional test results that go beyond standard reporting so you can trust your project will have the best possible outcome. Each of our steel bars come with full traceability and Mill certificates supplied as requested by you. Should you have a project that requires tracing later, we record every transaction with heat numbers and store them on site for such events. We offer this peace of mind at no additional charge. Having been in business since 1960, under the same ownership group, gives you the assurance we’ll be here when you need us.

Industries we service

Vanguard Steel Ltd. is a dynamic company with a diverse portfolio of services that cater to a wide range of industries, providing innovative solutions, precision, and quality. Let’s explore the industries Vanguard Steel Ltd. serves:

Robotics: In the field of robotics, Vanguard Steel provides specialized alloy steel. Their steel supplies machine shops with precision-engineered steel. Whether in robotic industries, manufacturing to healthcare.

Welding and Fabrication: Vanguard Steel supplies custom shops with additional options for them to fabricate structures, equipment, and machinery that meet the highest industry standards.

Agriculture: Agriculture relies on durable and reliable equipment, and Vanguard Steel caters to this sector by supplying robust steel bars and shafting for agricultural machinery. Their steel will be designed to withstand the rigours of farming, contributing to increased efficiency and productivity.

Oil and Gas: In the oil and gas industry, safety and reliability are paramount. Vanguard Steel delivers high-quality materials for the sector’s demanding applications, ensuring the integrity of critical equipment and systems used in exploration, production, and transportation.

Green Energy: As the world shifts toward sustainable energy sources, Vanguard Steel plays a crucial role by providing quality steel for green energy technologies such as wind turbines and solar power systems. These components are designed to endure challenging environmental conditions.

Conveyor Systems: Conveyor systems are the backbone of various manufacturing and distribution processes. Vanguard Steel supplies shafting for conveyor components that are engineered for durability and efficiency, contributing to the seamless flow of materials and goods in industries ranging from logistics to mining.

Construction: Vanguard Steel provides machinery steel to various manufacturers that build machinery to support the construction industry which is essential for the development of infrastructure and buildings.

Cargo and Shipping: In the cargo and shipping industry, reliable equipment is essential for the smooth transportation of goods. Vanguard Steel supplies specialty steel ensuring the quality and longevity of cargo handling equipment and components, facilitating the global movement of products.

With a commitment to precision, durability, and innovation, Vanguard Steel continues to be a trusted partner for industries locally and worldwide, helping them achieve their goals while maintaining the highest standards of quality.

SOURCING SPECIALIST

If you have difficulty sourcing material, try our team.

We have a network that spans the globe and our sourcing department evaluates current and potential suppliers for quality, delivery, and cost objectives so you can spend your time focusing on issues that matter to you.

Whether it’s:

•Nickel,

•Copper & Bass

•17-4PH,

•Manganese

•Aircraft Alloy

Etc…

give us a try. You have nothing to lose. We might even surprise you.

call our office at

1-866-294-3191 or 1-604-294-3191

Stainless, Carbon, Aircraft Alloys, Super Alloys, Electrical Steel, Aluminum, Brass/Bronze, DOM St52.3, 1026 Seamless Steel Tubing 1016 . 1524. 4130. 4140. 9Cr. 13Cr. A106-B/C. API 5LX-70, ID Chome Plated Tubing, Pneumatic Cylinder Tubing Alum. Steel. Stainless Steel Tubing. Brass Tubing, Hydraulic Fluid Line Tubing Carbon and Stainless, OD Ground and Chrome Plated Tubing Steel. Ground and Hard Chrome-Plated, SW85, 10V45, 1050, SW115 Chrome-plated……

© 2025 Vanguard Steel Ltd. All Right Reserved