Menu

For more information, click on image below

All our new slings are:

PROOF TESTED by our factory.

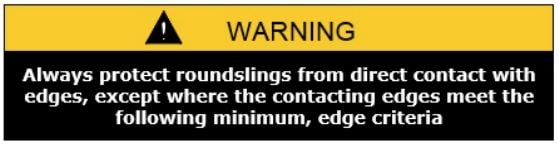

The Number One Cause of Sling Accidents!

Synthetic type slings can become cut or damaged if they are allowed to come into direct contact with edges if the

edges are not suitably well rounded. Such edges can include both the edges of the load as well as the edges of the

connection hardware.

[WSTDA-RS Section 5.4]

Ensuring Safety and Reliability:

Understanding Polyester Sling Longevity

Polyester sling shelf life is a critical consideration in ensuring workplace safety and maintaining equipment reliability. While the ASME B30.9 standard doesn’t explicitly outline a shelf life for polyester slings, understanding their longevity is pivotal for risk mitigation and operational efficiency. Despite the absence of specific guidelines, various factors influence the shelf life of polyester slings.

Environmental conditions significantly impact their durability. Exposure to UV radiation, extreme temperatures, moisture, and chemicals can accelerate degradation, reducing the sling’s strength and integrity over time. Regular inspections become crucial to assess any wear, cuts, abrasions, or chemical damage that could compromise the sling’s performance.

Manufacturer recommendations often offer insights into the expected lifespan of polyester slings, considering factors like usage frequency, load capacity, and maintenance practices. However, adherence to inspection criteria outlined in ASME B30.9 remains essential. Periodic inspections, regardless of the absence of stipulated shelf life, enable timely identification of wear or damage, allowing for replacement before potential failures occur.

The absence of a defined shelf life underscores the significance of proactive maintenance and adherence to industry standards. Employing a conservative approach by periodically replacing slings based on manufacturer guidance, usage patterns, and thorough inspections ensures a safer working environment and preserves equipment reliability. Regular evaluations and prudent replacements safeguard against unforeseen failures, promoting workplace safety and operational continuity.

Polyester Web Slings:

UV Exposure Limits and Service Retirements

Polyester web slings are a durable choice for lifting, but their exposure to UV or outdoor elements over time can compromise their integrity. When the cumulative impact of UV or outdoor exposure reaches specific limits, these slings should be permanently retired from service. This careful assessment ensures safety and reliability in lifting operations, preventing any potential risks that might arise from weakened material due to prolonged exposure to environmental factors. Regular monitoring and adherence to these limits are essential to maintain a secure and efficient lifting environment, prioritizing the safety of all involved.

EYE AND EYE MECHANICALLY PRESSED FLEMISH SLEEVES

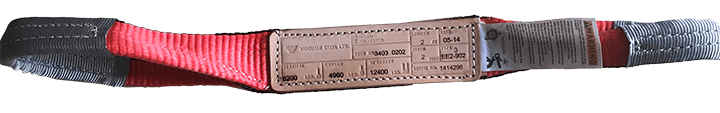

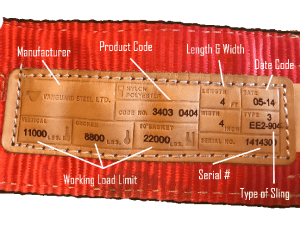

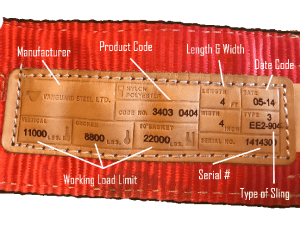

Understanding Sling Types and Tag info

L – Series

The leather safety tag doesn’t crack or wear like the plastic ones giving you longer service life.

- Manufacturer

- Product Code

- Length & Width

- Date Code

- Working Load Limit

- Serial Number

- Type of Sling

| WEB SLING CHEMICAL CHART FOR SAFE USE | ||

|---|---|---|

| Nylon | Polyester | |

| Acid | NO | NO |

| Alcohol | OK | OK |

| Aldehydes | OK | NO |

| Strong Alkalies | OK | ** |

| Bleaching Agents | NO | OK |

| Dry Cleaning Solvents | OK | OK |

| Ethers | OK | NO |

| Halogenated Hyrocarbons | OK | OK |

| Hydrocarbons | OK | OK |

| Ketones | OK | OK |

| Oil Crude | OK | OK |

| Oil Luberication | OK | OK |

| Soaps Detergents | OK | OK |

| Water Seawater | OK | OK |

| Weak Alkalies | OK | OK |

| ** Degraded by strong alkalies at elevated temperatures |

Vanguard’s Product info

| FLAT SLINGS | |||

|---|---|---|---|

| Sling Ply | |||

| Vertical WLL | Width | Product Codes | |

| Type 3 | 1600 | 1″ | 3403-11xx |

| 3200 | 2″ | 3403-12xx | |

| 4700 | 3″ | 3403-13xx | |

| 6200 | 4″ | 3403-14xx | |

| Double Ply | |||

| Type 3 | 3100 | 1″ | 3403-01xx |

| 6200 | 2″ | 3403-02xx | |

| 8800 | 3″ | 3403-03xx | |

| 11000 | 4″ | 3403-04xx | |

| 16500 | 6″ | 3403-06xx | |

| Type 4 | 3100 | 1″ | 3404-01xx |

| 6200 | 2″ | 3404-02xx | |

| 8800 | 3″ | 3404-03xx | |

| 11000 | 4″ | 3404-04xx | |

| 16500 | 6″ | 3404-06xx | |

| Type 5 | 6200 | 1″ | 3405-01xx |

| 12400 | 2″ | 3405-02xx | |

| 17600 | 3″ | 3405-03xx | |

| 22000 | 4″ | 3405-04xx | |

| xx – Length in feet |

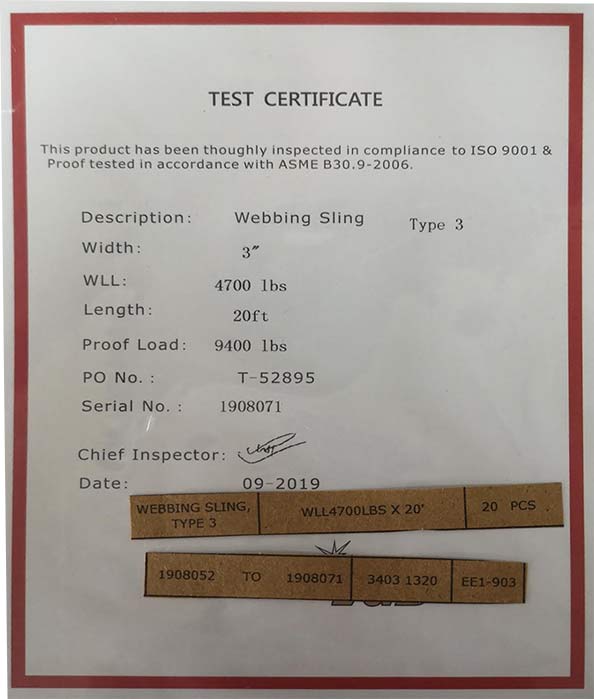

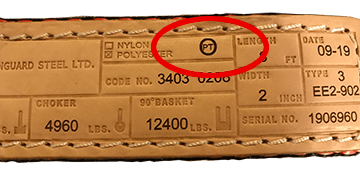

PT - LEATHER PROOF TESTED SLINGS

Proof Tested

Vanguard introduces an industry first, Proof Tested polyester slings done by their factory thereby not voiding the integrate of the sling and warrantee as stated in other manufactures fine print.

The new tags have “PT” stamped on them for quick identification.

P=Proof

T=Tested

A certificate with details is supplied with each sling. You will know by the markings that all measures have been taken in the testing of each sling.

One extra piece of mind showing you that Vanguard goes the extra mile.

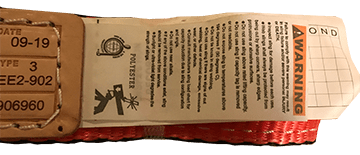

Above picture shows the standard warning tag most slings come with.

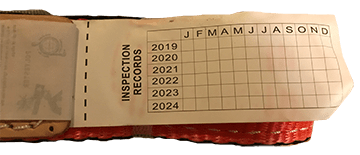

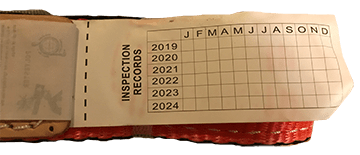

Below’s picture shows the added Inspection Report tag we have secured to each of our slings. Safety is at the heart of everything we do.

Amid the multitude of sling manufacturers offering both quality and knockoff products, determining the authenticity and quality of a sling can be a challenge based solely on visual inspection. Several factors can be considered:

Manufacturer’s Reputation: Checking the track record of the manufacturer is a promising starting point. However, it’s often difficult to ascertain if the sling was produced by the manufacturer directly or under a distributor’s private label program, adding an element of uncertainty.

Consistency in Appearance: Manufacturers can alter their sources or quality while maintaining a consistent appearance. This means that relying solely on the visual aspects of the sling may not provide a full picture of its quality.

Physical Inspection Limitations: While a physical inspection can offer some insights, it may not always be practical, especially when making remote or online purchases. Assessing factors like correct stitching and the grade of polyester can be challenging.

Proof Testing: Proof testing, where each sling is subjected to a pull test at 150% of the working load, is the most reliable way to validate a sling’s quality. However, it is an expensive and time-consuming process. Additionally, some manufacturers may prohibit proof loading, as it could void their warranties, necessitating written permission.

Fortunately, our commitment to quality assurance removes this burden for you. Our factory conducts Proof Testing on all LPT slings, ensuring they meet the quality standards you expect and the performance you’re paying for. This means that critical lifts become less of a concern, offering you peace of mind in your sling’s reliability and performance.

Our factory is: ISO 9001:2015 Certified and a member of LEEA (Lifting Equipment Engineers Association)

Inspection requirements

ASME B30.9 Standards of Inspection on Synthetic Web Slings

Web Sling Inspections and Frequency

All inspections shall be performed by a designated person with any deficiencies further examined by a qualified person to identify hazards and determine what additional steps need to be taken to address the hazard.

ASME B30.9.

Initial Inspection (prior to initial use)

Under best practice it is important to inspect the synthetic web sling to make sure it is what you ordered. The ratings and tags are correct and record the serial number in your log book.

(Written records are not required for initial inspection)

Frequent (daily or prior to use)

Designate a Competent Person* to perform a daily visual inspection of slings and all fastenings and attachments for damage as laid out in the removal section. The inspector should also make sure that the web sling that was selected meets the specific job requirements it’s being used for.

*Competent Person- as laid out in ASME B30.9

A Once-a-day inspection might not be enough if the sling is used multiple times throughout the day under extreme conditions. Shock loads, sharp edges, excessive heat etc. can quickly damage the integrity of the web sling so you will need to develop a ‘best practice’ guideline for your working condition.

(Written records are not required for frequent inspection, however, a ‘best practice’ guideline should be in place)

Periodic Inspection

A periodic inspection shall be performed by a Qualified Person no later than 1 year (at a minimum) More frequent in severe service conditions. The following are all determining factors in scheduling the frequency of a periodic inspection:

Frequency of use

Severity of service conditions

Nature of the lifts being performed

Experience gained on the service life of web slings used in similar applications

ASME provides these additional periodic inspection guidelines based on the service of the synthetic web sling:

Normal Service – Yearly

Severe Service – Monthly to Quarterly

Special Service – As recommended by a Qualified Person

Depending on the severity of the operating environment and frequency of use, your business may decide that a more thorough sling inspection should occur more often than the minimum yearly requirement.

Periodic inspections are required to be documented per ASME B30.9 and record retained. The employer is required to maintain a record of the most recent thorough inspection—however, individual records for each sling that was inspected are not required. Maintaining a ‘best practice’ strategy for recording your slings and which ones have been inspected should make producing records in the event of an accident.

Per ASME B30.9, each synthetic web sling shall be marked by the manufacturer to include:

- Name or trademark of the manufacturer, or if repaired, the entity performing the repair

- Manufacturer’s code or stock number

- Rated load for at least one hitch type and the angle at which it is based

- Type of synthetic web material

- Number of legs, if more than one

It is the responsibility of the user to maintain the sling identification—ensuring the tag or identification is still in place and is still legible during the life of the sling. If the identification tag is missing or illegible, it is the responsibility of the inspector to remove the sling from service.

Basic Inspection Criteria for Synthetic Web Slings

When inspecting web slings, daily visual inspections are intended to detect serious damage or deterioration which would weaken the strength and integrity of the sling.

This inspection is usually performed by the person using the sling in a day-to-day job. If during any point of the inspection the following is observed, the web sling should be removed from service and be discarded:

- Missing or illegible sling identification

- Acid or caustic burns

- Melting or charring of any part of the sling

- Holes, tears, cuts, or snags

- Broken or worn stitching in load-bearing splices

- Excessive wear or abrasion

- Knots in any part of the sling

- Discoloration and brittle or stiff areas on any part of the sling, which may indicate chemical or UV damage

- Fittings that are pitted, corroded, cracked, bent, twisted, gouged, or broken

- For hooks, removal criteria as stated in ASME B30.10

- For rigging hardware, removal criteria as stated in ASME B30.26

- Other conditions, including visible damage, that cause doubt to the continued use of the sling

ASME B30.9 standards specify that a synthetic web sling shall be removed from service immediately if any of the following conditions are present: