Brushes

CATALOGUE

Click on booklet to view content

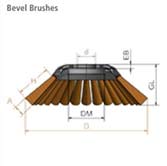

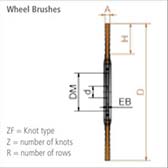

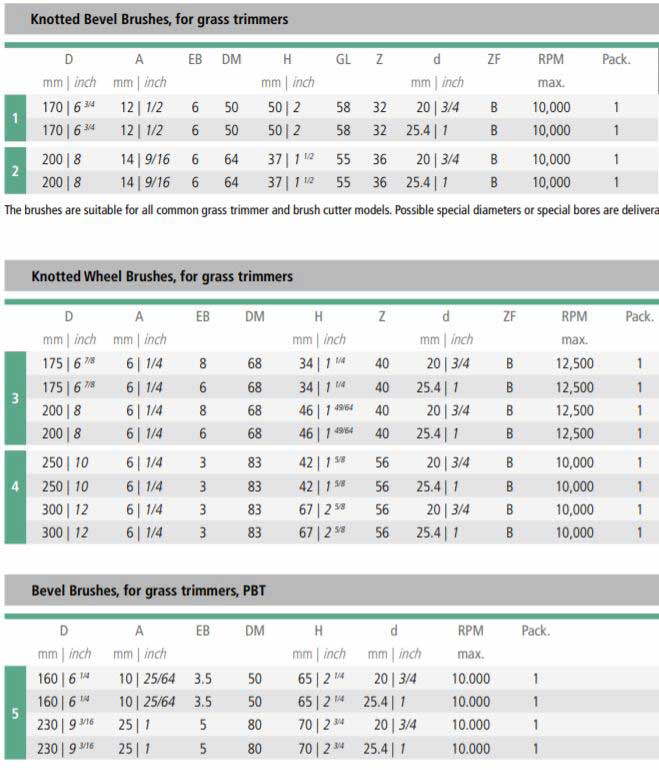

Brushes for grass trimmers

Brushes for grass trimmers

Knotted brushes or Bevel Brushes with PBT on grass trimmers are ideal for removing weeds on grass pavers, curbstones, cobbled areas or other spots which are hard to reach. Those brushes clean larger areas like courtyards, terraces or longer alleys effortless and sustainable.

Besides, brushes are ecologically friendly and they remove weeds fast and effectively.

In sensitive areas such as agriculture, synthetic filaments are a decisive criterion. Synthetic bristles are soft and therefore ideally suited for sensitive surfaces, as they do not scratch. The brush with synthetic bristles is ideal for grass trimmers with battery due to its lighter

weight and scores with longer service life and even wear.

STM = brass coated steel, straight

STH = steel wire, high tensile, straight

PBT = Polyester PBT

Attention: When working with brushes on grass trimmers, please be aware of stringent safety rules. Please take note of the datasheet we attach the brushes or have a look at www.lessmann.com.

Low sparking brushes

Low sparking brushes

are recommended for working in areas where flammable steams, liquids, or dust are a part of the working conditions. Also, they

are used in all other situations where sparks could lead to a potential fire or explosion

hazard.

In explosion-proof areas, low sparking brushes are recommended. In comparison to the wooden handles of the hand brushes, the bodies of machine-driven brushes are made of brass. The filling material is bronze CuSn6. These materials generate a low amount of sparks, which ensures a working environment

with the minimum of sparks.

Another benefit of bronze is its corrosion-resistant properties.

Typical application areas

Low sparking brushes are used in all industries and companies which have explosion risks or fire hazards due to flying sparks. e.g.:

• Oil and gas industry

• Pipeline industry

• Chemical industry

• Nuclear power plants

• Plastics industry

• Food industry, e.g.: bakeries

• And many others

For example, cleaning tanks or working in an explosive environment.

Work instructions

• Low sparking brushes (with bronze filling) are a lot softer than other regularly used fill materials e.g. Steel and Stainless Steel

• Therefore these brushes have a higher abrasion rate, this means these brushes have to be used with more carefully so as not to damage the workpiece.

Video Tutorial

pages

- Mailer

- Marking GP Shackles

- ANTOX

- Cable & Wire Rope

- Firefighting Promo Page 2024

- What is VGD?

- What is VQ

- Paperless

- University of Vanguard

- Abrasives/Brushes

- Firefighting Promotion Thank you

- Firefighting Promotion Order Form

- Calculators

- Resources and Useful Links

- STEEL WEIGHT CALCULATOR

- Specialty Steel

- Hardware

- Contact

- Industrial Knives

- Welding

- Home

© 2024 Vanguard Steel Ltd. All Right Reserved