- 1-866-294-3191

- Open Monday to Friday 8am to 5pm

- Emergency Callout Available

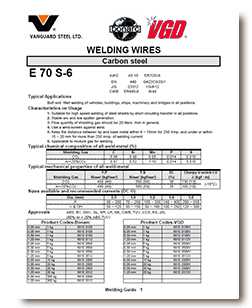

ER70S-6

Suitable welding positions

AWS A5.18 ER7OS-6

EN 440 G422CG3Si1

JIS Z3312 YGW12

CWB ER495-6 W48

Typical applications

Widely used in the fabrication of auto parts, truck bodies, heavy equipment and farm implements. Also commonly used for HVAC duct work, structural applications, pipes, steel castings or forgings, shaft build-ups and general shop fabrications.

Mild steel wire for welding of mild steel and 490MPa tensile strength materials.

Characteristics on usage

- Suitable for high speed welding of steel sheets by short circuiting transfer in all positions.

- Stable arc and low spatter generation.

- Flow quantity of shielding gas should be 20 liters /min in general.

- Use a wind-screen against wind.

- Keep the distance between tip and base metal within 6 ~ 15mm for 250 Amp. and under or within 15 ~ 20 mm for more than 250 Amp. of welding current.

- Applicable to mixture gas for welding.

Typical chemical composition of all-weld-metal (%)

CWB to CSA W48-14

Classification: B-G 49A 3 C1 56 (B-G 49A 3 C GG)

AWS/ASME A5.18/A5.18M:2005

Typical chemical composition of all-weld-metal (%)

| Shielding Gas | C | Si | Mn | P | S | ||||||||||||||||||||||||||||||||||

| CO2 | 0.08 | 0.50 | 0.05 | 0.014 | 0.010 | ||||||||||||||||||||||||||||||||||

| Ar+20%CO2 | 0.07 | 0.52 | 1.10 | 0.014 | 0.010 | ||||||||||||||||||||||||||||||||||

Sizes available and recommended currents (DC +)

| Dia. (mm) | 0.9 | 1.0 | 1.2 | 1.4 | 1.6 | ||||||||||||||||||||||||||||||||||

| F | 50 ~ 200 | 70 ~ 250 | 100 ~ 350 | 140 ~ 400 | 200 ~ 550 | ||||||||||||||||||||||||||||||||||

| V & OH | 50 ~ 120 | 50 ~ 150 | 50 ~ 180 | 100 ~ 250 | 120 ~ 300 | ||||||||||||||||||||||||||||||||||

Approvals

ABS, BV, DNV, GL, KR, LR, NK, CWB, TUV, CCS, KS, JIS, (80% Ar + 20% ABS TUV)

Typical mechanical properties of all-weld-metal

| Shielding Gas | Y.P N/mm² {kgf/mm²} | T.S N/mm² {kgf/mm²} | EI. (%) | Charpy V-notch I.V J {kgf · m} | ||||||||||||||||||||||||||||||||||||||||

| CO2 | 450 {46} | 550 {56} | 30 | 130 {13} | (-18°C) | |||||||||||||||||||||||||||||||||||||||

| Ar+20%CO2 | 480 {49} | 580 {59} | 28 | 100 {10} | ||||||||||||||||||||||||||||||||||||||||

Product Codes

| Product Codes-Bonarc | ||||||||||||||||||||

| 0.6 mm .023 | 1 kg | 6910 0106 | ||||||||||||||||||

| 0.8 mm .030 | 1 kg | 6910 0108 | ||||||||||||||||||

| 0.9 mm .035 | 1 kg | 6910 0109 | ||||||||||||||||||

| 1.20 mm .045 | 1 kg | 6910 0112 | ||||||||||||||||||

| 0.6 mm .023 | 5 kg | 6910 0506 | ||||||||||||||||||

| 0.8 mm .030 | 5 kg | 6910 0508 | ||||||||||||||||||

| 0.9 mm .035 | 5 kg | 6910 0509 | ||||||||||||||||||

| 1.20 mm .045 | 5 kg | 6910 0512 | ||||||||||||||||||

| 0.6 mm .023 | 15 kg | 6910 2006 | ||||||||||||||||||

| 0.8 mm .030 | 20 kg | 6910 2008 | ||||||||||||||||||

| 0.9 mm .035 | 20 kg | 6910 2009 | ||||||||||||||||||

| 1.20 mm .045 | 20 kg | 6910 2012 | ||||||||||||||||||

| 0.9 mm .035 | 300 kg | 6910 0309 | ||||||||||||||||||

| 1.20 mm .045 | 300 kg | 6910 0312 | ||||||||||||||||||

| Product Codes-VGD | ||||||||||||||||||||

| 0.6 mm .023 | 1 kg | 6910 0106V | ||||||||||||||||||

| 0.8 mm .030 | 1 kg | 6910 0108V | ||||||||||||||||||

| 0.9 mm .035 | 1 kg | 6910 0109V | ||||||||||||||||||

| 1.20 mm .045 | 1 kg | 6910 0112V | ||||||||||||||||||

| 0.6 mm .023 | 5 kg | 6910 0506V | ||||||||||||||||||

| 0.8 mm .030 | 5 kg | 6910 0508V | ||||||||||||||||||

| 0.9 mm .035 | 5 kg | 6910 0509V | ||||||||||||||||||

| 1.20 mm .045 | 5 kg | 6910 0512V | ||||||||||||||||||

| 0.6 mm .023 | 15 kg | 6910 2006V | ||||||||||||||||||

| 0.8 mm .030 | 20 kg | 6910 2008V | ||||||||||||||||||

| 0.9 mm .035 | 20 kg | 6910 2009V | ||||||||||||||||||

| 1.20 mm .045 | 20 kg | 6910 2012V | ||||||||||||||||||

pages

- Marking GP Shackles

- ANTOX

- Cable & Wire Rope

- Firefighting Promo Page 2024

- What is VGD?

- What is VQ

- Paperless

- University of Vanguard

- Abrasives/Brushes

- Firefighting Promotion Thank you

- Firefighting Promotion Order Form

- Calculators

- Resources and Useful Links

- STEEL WEIGHT CALCULATOR

- Specialty Steel

- Hardware

- Contact

- Industrial Knives

- Welding

- Home

© 2024 Vanguard Steel Ltd. All Right Reserved