- 1-866-294-3191

- Open Monday to Friday 8am to 5pm

- Emergency Callout Available

VGD - Tiedown straps

Secure Your Cargo with VGD Tiedown Straps

When transporting cargo safely and securely, having the right equipment is essential.

However, many standard tiedown straps on the market today lack the durability and reliability needed to withstand the rigours of transportation, leading to potential safety hazards and damage to your cargo.

Enter VGD Tiedown Straps – the ultimate solution for confidently securing your cargo. Built to last, our heavy-duty straps are designed with a low stretch factor and high-quality stitching, ensuring your load stays firmly in place, no matter the conditions.

Our heavy-duty VGD tiedown straps are designed for reliability and safety during transport. With a low stretch factor and high-quality stitching, these straps ensure that your cargo remains securely in place, even under the toughest conditions. The forged D-ring provides a strong anchor point for attachment, giving you peace of mind knowing that your load is secure. Whether you’re transporting goods on a truck bed or securing equipment on a trailer, trust VGD tiedown straps to keep your cargo safe and secure throughout the journey.:

Low Stretch Factor: VGD tiedown straps are designed to have minimal stretch under tension. This property ensures that the straps maintain their tightness and hold the cargo securely in place without loosening during transportation. Low stretch also contributes to stability, preventing the cargo from shifting or moving excessively.

High-Quality Stitching: These straps typically feature high-quality stitching, which adds to their durability and load-bearing capacity. Strong stitching ensures that the straps can withstand heavy loads and the stresses of transportation without fraying or coming apart.

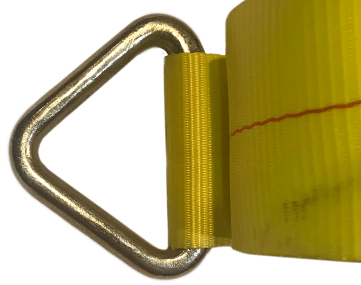

Forged D-Ring: The presence of a forged D-ring provides a sturdy anchor point for attaching the strap to a winch or other fastening mechanisms. The forged construction enhances the strength and reliability of the D-ring, ensuring it can handle significant tension without bending or breaking.

VQ Polyester Winch Strap w/D Ring

Pre-made grade 70 tie-down chain complete with grab hooks both ends and safety tags. Comes in a convenient plastic pail for storage and carrying.

V7 stamped on the link for quality identification

Vanguard quality of more than 50 years stands behind this product.

VQ Polyester Winch Strap w/D Ring

Winch straps are the most common tie downs for flatbed trailer loads.

Made of durable polyester webbing, providing excellent retained tension on rigid loads.

It has excellent recovery properties that help absorb impact without strap breakage.

Does not absorb moisture, shrink or stretch.

High visible yellow to make it easily discernible from most background.

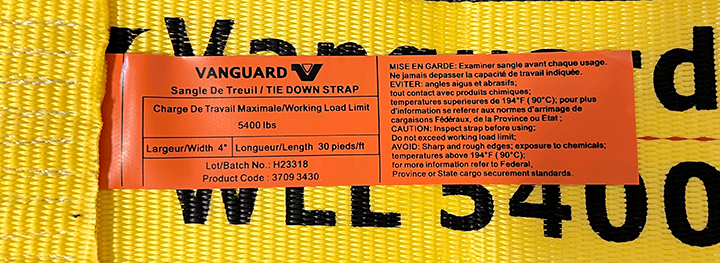

Each strap is printed on the webbing every 4ft:

Vanguard Steel Ltd

WLL 5400lbs

| Width | Length | End Fitting | Weight lbs.pc. | WLL (lbs) | Product Code |

|---|---|---|---|---|---|

| 4" | 30ft | D Ring | 3.90 | 5400 | 3709 3430 |

What is a winch strap used for?

A polyester winch strap with a D-ring is a heavy-duty strap designed for securing cargo during transportation, often used in conjunction with winches. The strap is typically made of polyester material, known for its strength, durability, and resistance to stretching. The D-ring is a metal or sturdy plastic ring attached to one end of the strap, providing a secure anchor point for hooking onto a winch or other fastening mechanisms.

These straps are commonly used in the trucking and transportation industry to secure loads on flatbed trailers, trucks, or other hauling vehicles. The polyester material offers high tensile strength and resistance to abrasion, making it suitable for handling heavy loads and enduring harsh conditions during transportation.

The D-ring allows for easy attachment and tensioning using winches or ratcheting mechanisms, providing a reliable way to tighten and secure the strap around the cargo, ensuring it stays in place during transit. The combination of polyester material and the D-ring makes this type of strap a versatile and essential tool for safely securing various types of cargo for transportation.

Exploring Winch Straps: Key Queries Answered

What are the key features to consider when choosing a winch strap?

- When considering winch straps, crucial factors like material, width, and length significantly impact their performance. The Vanguard polyester winch straps, boasting a robust 4-inch width and 30 feet length, offer substantial coverage for securing various loads. Their notable safe working load of 5400 lbs reflects a reliable capacity to handle substantial weights without compromising safety. This combination of polyester material and generous dimensions makes these straps a sturdy and dependable choice for securing cargo during transportation.

How do I properly use a winch strap?

Properly using a winch strap is essential for both securing cargo effectively and ensuring safety during transportation. Here’s a step-by-step guide:

Choose the Right Strap: Ensure the winch strap’s specifications match the load you’re securing. Check its safe working load and other relevant details.

Inspect the Strap: Before use, inspect the entire length of the strap for any signs of damage, wear, or weaknesses. Replace the strap if you notice any issues.

Thread the Strap: Insert one end of the winch strap through the winch drum or attachment point on the vehicle or trailer. Make sure it’s threaded correctly to prevent twisting or improper tensioning.

Secure the Cargo: Wrap the loose end of the winch strap around the cargo and feed it back through the winch mechanism. Ensure the strap lies flat against the cargo without twists or knots.

Tension the Strap: Engage the winch mechanism and start tightening the strap. Use the winch handle or crank to create tension gradually. Avoid sudden or jerky movements that could damage the strap or the cargo.

Check Tension and Security: Confirm that the strap is securely tightened around the cargo. Check for any slippage or looseness and readjust if necessary.

Secure Excess Length: If there’s excess strap length after securing the cargo, secure it properly to prevent flapping or getting caught during transit. Some straps have mechanisms or hooks for securing the loose end.

Periodic Checks: During transportation, periodically check the tension and security of the strap. Vibrations and movements might cause slight loosening, so re-tighten if needed.

Unload Safely: When unloading, release the tension on the winch strap gradually and carefully to avoid sudden movements or the cargo shifting unexpectedly.

Remember, always follow the manufacturer’s instructions and guidelines specific to your winch strap. Proper usage not only secures your cargo effectively but also ensures the longevity of the winch strap itself. Safety should be the priority throughout the process.

What maintenance is required for winch straps?

Maintaining winch straps is essential for ensuring their longevity and optimal performance. Here are some key maintenance steps:

- Regular Inspection: Periodically examine the entire length of the strap for any signs of wear, cuts, fraying, or abrasions. Pay close attention to the stitching, as any loose threads or damage could compromise the strap’s strength.

- Cleaning: Clean the winch straps after each use, especially if they’ve been exposed to dirt, grime, or chemicals during transportation. Use mild soap and water to remove any debris or contaminants. Avoid using harsh chemicals that might degrade the material.

- Storage: Store winch straps in a clean, dry, and cool environment when not in use. Keep them away from direct sunlight and extreme temperatures, as these conditions can weaken the material over time.

- Avoid Overloading: Never exceed the safe working load limit specified for the winch strap. Overloading can weaken the material and compromise its strength, leading to potential failure during use.

- Replace Damaged Straps: If you notice any significant damage, cuts, or signs of wear that could compromise the integrity of the strap, replace it immediately. Don’t take risks with compromised equipment.

By conducting regular inspections, cleaning when necessary, proper storage, avoiding overloading, and promptly replacing damaged straps, you’ll ensure that your winch straps remain in good condition and reliable for securing cargo.

What is the weight limit or capacity of a winch strap?

The weight limit or capacity of a winch strap is typically indicated by its “Safe Working Load” (SWL). This is the maximum weight the strap is rated to handle under normal working conditions.

The Safe Working Load is specified by the manufacturer and can vary based on the material, width, length, and construction of the winch strap. It’s crucial to adhere to this limit to ensure the strap’s integrity and prevent accidents or damage during transportation.

Exceeding the Safe Working Load can compromise the strength of the strap, leading to potential failure or breakage, risking harm to individuals or damage to the cargo. Always verify the Safe Working Load of the winch strap and ensure that the load being secured does not exceed this specified limit.

What are the regulations or standards for using winch straps?

Regulations and standards for using winch straps can vary depending on the region, industry, and the specific application. Here are some general guidelines and aspects commonly considered:

Federal and State Regulations: Different countries or regions might have specific regulations governing the use of winch straps. These regulations often outline standards for load securement, including the types of straps allowed, their specifications, and how they should be used to ensure safety during transportation.

Industry Standards: Various industries, such as transportation, shipping, or construction, might have their own set of guidelines or standards for securing cargo using winch straps. These standards often emphasize best practices for load securement based on the type of cargo being transported.

Strap Specifications: Manufacturers often provide guidelines and recommendations for the proper use of their winch straps. These specifications cover details like Safe Working Load, material care, maintenance, and proper usage to maximize the strap’s lifespan and effectiveness.

Inspections and Compliance: Regular inspections of equipment, adherence to weight limits, proper tensioning, and securement methods are often part of regulatory compliance. Ensuring compliance with these regulations helps prevent accidents and ensures the safety of both cargo and individuals involved in transportation.

Training and Certification: Some industries require specific training or certification for individuals involved in load securement. This training covers proper techniques for using winch straps, understanding regulations, and ensuring compliance with industry standards.

It’s crucial to stay informed about relevant regulations and standards applicable to your region and industry to ensure compliance and promote safety when using winch straps for securing cargo during transportation. Consulting regulatory bodies, industry organizations, or seeking guidance from experienced professionals can help ensure adherence to these guidelines.

pages

- Marking GP Shackles

- ANTOX

- Cable & Wire Rope

- Firefighting Promo Page 2024

- What is VGD?

- What is VQ

- Paperless

- University of Vanguard

- Abrasives/Brushes

- Firefighting Promotion Thank you

- Firefighting Promotion Order Form

- Calculators

- Resources and Useful Links

- STEEL WEIGHT CALCULATOR

- Specialty Steel

- Hardware

- Contact

- Industrial Knives

- Welding

- Home

© 2024 Vanguard Steel Ltd. All Right Reserved